cnc 5-axis machining A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it . A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

In this blog post we'll go through the five top advantages of lunch boxes made of stainless teel! 1. Good durability. Stainless steel is a very robust material. Even if your lunch box falls down on hard ground, it won’t be severely damaged.

what is 5 axis milling

A 5-axis CNC machine allows the machining of five surfaces simultaneously. For conventional 3-axis machining, you may need several setups to work on parts with several . A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it .

what does 5 axis mean

5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This .

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it .

With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis .

5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, .

At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three .This CNC machine guide will relieve the complexity surrounding 5-axis machines, how they work and why you might need one in your shop.

FANUC’s advanced 30i and 31i-5 CNCs look-ahead in the part program by up to 1000 blocks, making intelligent decisions to improve part quality and optimize cutting speeds. The CNC .

small 5 axis cnc mill

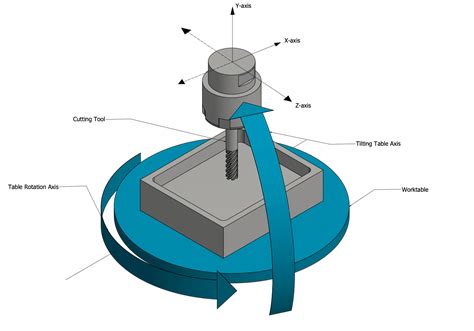

Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process. A 5-axis CNC machine allows the machining of five surfaces simultaneously. For conventional 3-axis machining, you may need several setups to work on parts with several faces. But the 5-axis technology completes the machining of contoured parts and other parts with many faces in a single structure. A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision. 5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This sophisticated control system enables the machining of complex geometries with unprecedented flexibility and efficiency.

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency.

At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.

This CNC machine guide will relieve the complexity surrounding 5-axis machines, how they work and why you might need one in your shop.

FANUC’s advanced 30i and 31i-5 CNCs look-ahead in the part program by up to 1000 blocks, making intelligent decisions to improve part quality and optimize cutting speeds. The CNC handles the large part programs with ease, providing up to 8MB of internal memory, up to 4GB of external ATA flash memory, and high-speed Ethernet transfers. Full 5-axis CNC machining means a machine’s processing ability to move a tool or a workpiece in five different axes simultaneously. 5-axis CNC machining is considered a more evolved and sophisticated version of the CNC machining process. A 5-axis CNC machine allows the machining of five surfaces simultaneously. For conventional 3-axis machining, you may need several setups to work on parts with several faces. But the 5-axis technology completes the machining of contoured parts and other parts with many faces in a single structure. A 5-axis CNC machine allows the machining of five different surfaces simultaneously. This dynamic movement grants the machine unparalleled freedom to approach the workpiece from any angle, making it ideal for producing intricate and complex geometries with exceptional precision.

5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This sophisticated control system enables the machining of complex geometries with unprecedented flexibility and efficiency. Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .

With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of . 5 axis CNC machining uses a machine that can simultaneously move and rotate in five axes to machine a part. Its benefits include its high suitability for fabricating parts with complex designs and intricate details, accuracy, speed, and production efficiency. At its core, 5-axis machining refers to the capability of a CNC machine to move a part or a tool on five different axes simultaneously. Traditional 3-axis machines operate on the X, Y, and Z axes, allowing movement in three primary directions: up and down, left and right, and forward and backward.This CNC machine guide will relieve the complexity surrounding 5-axis machines, how they work and why you might need one in your shop.

buyers for cnc machined components

benefits of 5 axis machining

5 axis trunnion machining

5 axis machining explained

By your description, you're doing a dry run. It's just a term used to describe running the program through, but not cutting a part. Most machines have a "dry run" button on them, .

cnc 5-axis machining|5 axis trunnion machining