cheap sheet metal forming processes In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal . The smoke generator has air intake vents and if you have a small amount of air going into those vents, it should go through the generator and help push the smoke up and out. A low CFM fan or low speed fan placed a distance from the smoke gen should help if the trays are not blocking the air flow.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal operations with diagrams

4 · sheet metal forming process pdf

5 · sheet metal bending process pdf

6 · forming sheet metal by hand

7 · bulk deformation vs sheet metal forming

What is a Junction Box? A junction box is simply a small enclosure for electrical connections. It protects these electrical connections from the environment around them and accidental contact. The box itself isn't anything specific. They are typically made of metal or plastic and are attached to a beam or possibly the drywall.

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal .

Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively .

sheet metal working process pdf

sheet metal stamping process pdf

Sheet metal roll forming is one of the most affordable metal fabrication processes. The ability to manufacture large quantities of simple and complex quality parts makes roll forming a favorite in several industries, . Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. There is an extensive range of metal materials that are suitable for various . Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased .Sheet metal forming is the most cost-effective forming procedure today for manufacturing parts in large quantities. It can be highly automated in factories or, at the other end of the spectrum, manually operated in metal workshops for .

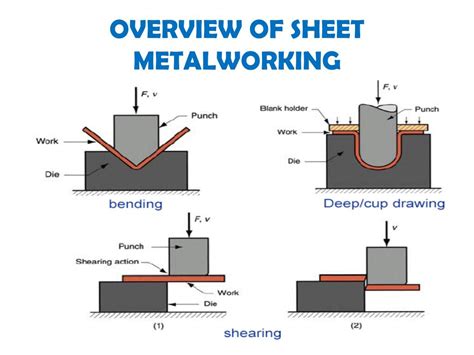

Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications. Get the inside scoop on sheet metal forming techniques and equipment used in the industry. Learn about the latest technology and tools to streamline your production process. In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, ..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision. Sheet metal roll forming is one of the most affordable metal fabrication processes. The ability to manufacture large quantities of simple and complex quality parts makes roll forming a favorite in several industries, including power distribution, commercial refrigeration, warehouse and data storage, and more.

Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. There is an extensive range of metal materials that are suitable for various sheet metal fabrication processes, including steel, aluminum, stainless steel, brass, copper, and zinc. Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased productivity, cost efficiency, flexibility & .Sheet metal forming is the most cost-effective forming procedure today for manufacturing parts in large quantities. It can be highly automated in factories or, at the other end of the spectrum, manually operated in metal workshops for small series parts.

Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications. Get the inside scoop on sheet metal forming techniques and equipment used in the industry. Learn about the latest technology and tools to streamline your production process. In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

sheet metal processes pdf

In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision. Sheet metal roll forming is one of the most affordable metal fabrication processes. The ability to manufacture large quantities of simple and complex quality parts makes roll forming a favorite in several industries, including power distribution, commercial refrigeration, warehouse and data storage, and more. Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. There is an extensive range of metal materials that are suitable for various sheet metal fabrication processes, including steel, aluminum, stainless steel, brass, copper, and zinc.

Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased productivity, cost efficiency, flexibility & .Sheet metal forming is the most cost-effective forming procedure today for manufacturing parts in large quantities. It can be highly automated in factories or, at the other end of the spectrum, manually operated in metal workshops for small series parts.

Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications.

Get the inside scoop on sheet metal forming techniques and equipment used in the industry. Learn about the latest technology and tools to streamline your production process.

sheet metal operations with diagrams

sheet metal forming process pdf

sheet metal bending process pdf

forming sheet metal by hand

Why are houses typically built with wood instead of steel? Wood is a popular choice for building houses because it is readily available, affordable, and easy to work with. It .

cheap sheet metal forming processes|sheet metal operations with diagrams