cnc machine hour rate Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes. There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC I’ll cover in this article: CNC router machine; CNC mills; CNC lathe machines; Wire EDM; EDM; CNC laser cutting machine; CNC grinders; CNC plasma .

0 · machinery cost per hour calculator

1 · machine cost per hour calculator

2 · how to calculate cnc cost

3 · cnc machine time cost

4 · cnc machine shop hourly rates

5 · cnc machine price calculator

6 · cnc machine hourly rate calculator

7 · cnc machine hourly rate

A junction box is a standard electrical box that encloses wire splices and contains no device (like a receptacle). What is a Type 1 junction box vs. a Type 2 junction box? The type 2 junction box is only for indoor use.

The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.Start by determining the hourly rate of your CNC machine, factoring in its purchase . Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, .

Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes.

As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining .With machine hourly rate calculator allows you to calculate the manufacturing, setup and programming hourly rate as a full cost accounting or contribution margin . Our online calculator includes all necessary manufacturing overhead .

CNC machine hour rate calculation consists of several cost components that contribute to the overall hourly rate. These components include direct costs, indirect costs, manpower costs, . To calculate the CNC machining cost per hour, you need to follow these steps: 1. Determine the machine rate: Start by identifying the hourly rate charged by the CNC machine used for manufacturing. This rate usually .

machinery cost per hour calculator

Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that . To understand the cost of CNC machining, it’s essential to delve deeper into the process itself. CNC, or Computer Numerical Control machining, is a manufacturing technique that uses automated, high-speed cutting tools to . The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.

Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.

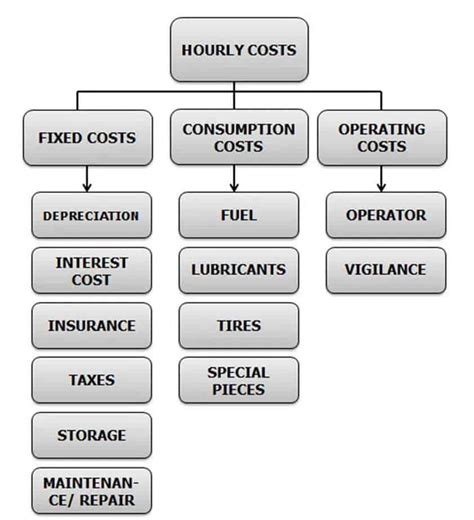

Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability.

Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes.As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.With machine hourly rate calculator allows you to calculate the manufacturing, setup and programming hourly rate as a full cost accounting or contribution margin . Our online calculator includes all necessary manufacturing overhead costs to calculate the machine hourly rate.CNC machine hour rate calculation consists of several cost components that contribute to the overall hourly rate. These components include direct costs, indirect costs, manpower costs, machine costs, overhead costs, and tooling costs.

To calculate the CNC machining cost per hour, you need to follow these steps: 1. Determine the machine rate: Start by identifying the hourly rate charged by the CNC machine used for manufacturing. This rate usually accounts for the depreciation cost of the machine, as well as maintenance and repair expenses. 2. Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that makes the perfect sense. To understand the cost of CNC machining, it’s essential to delve deeper into the process itself. CNC, or Computer Numerical Control machining, is a manufacturing technique that uses automated, high-speed cutting tools to form shapes from metals and plastics. The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor.

Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes.As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.

With machine hourly rate calculator allows you to calculate the manufacturing, setup and programming hourly rate as a full cost accounting or contribution margin . Our online calculator includes all necessary manufacturing overhead costs to calculate the machine hourly rate.

CNC machine hour rate calculation consists of several cost components that contribute to the overall hourly rate. These components include direct costs, indirect costs, manpower costs, machine costs, overhead costs, and tooling costs.

To calculate the CNC machining cost per hour, you need to follow these steps: 1. Determine the machine rate: Start by identifying the hourly rate charged by the CNC machine used for manufacturing. This rate usually accounts for the depreciation cost of the machine, as well as maintenance and repair expenses. 2. Setting down to calculate your CNC hourly rate is key to your future success. So how do you find your hourly in this daunting task? Well, there are a few different methods we can work through to help find that hourly rate that makes the perfect sense.

steel box tool

steel box section suppliers uk

Metal electrical boxes require screws with threads that can securely grip the metal surface, while non-metallic or plastic boxes may have specific screw requirements. Different types of electrical box screws include machine screws, self-tapping screws, wood screws, drywall screws, and anchor screws.

cnc machine hour rate|machinery cost per hour calculator