different sheet metal operations Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; . A Multi-Purpose stool made of exceptional quality, the SS6704 is welded in a durable, stainless steel construction. Standard Features: Tip-Resistant offset legs with rubber tips; Fast action 1" O.D. seat adjustment screw; Heavy duty threaded stem for seat height adjustments; Non-slip material mounted into recess of stool seat for a flush finish©2023 United Metal Fabricators Inc. dba UMF Medical Ultra Comfort Air Spring Stool Model 6749 All UMF Medical stools are available in 16 best-in-class seamless upholstery colors with .

0 · types of sheet metal pdf

1 · sheet metal operations pdf

2 · sheet metal bending diagram

3 · shearing operation in sheet metal

4 · notching operation in sheet metal

5 · name various sheet metal operations

6 · embossing operation in sheet metal

7 · drawing operation in sheet metal

Model: 5140. Brand: United Metal Fabricators. Call us at 858-367-9733 and save 10%. Note: This product has been discontinued and replaced by the UMF 5240 Exam Table. The UMF 5140 Exam Table is an excellent addition to your medical office. With the unique vacuum-formed top, these exam tables are seamless and exceptionally comfortable.

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what . Whether you’re in aerospace, automotive, or consumer electronics, understanding the various operations is vital for making informed manufacturing decisions. Read on and explore the different sheet metal operations to .

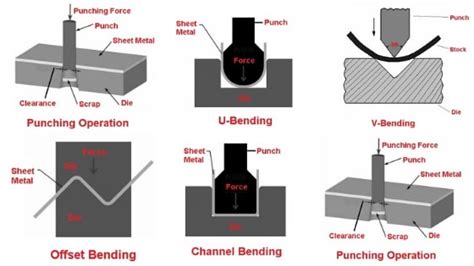

In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing . Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; . In this article, we will discuss the various types of Sheet Metal Operations. But before moving ahead to understand these operations, we should also understand what actually the sheet metal is. Sheet Metal: Sheet Metal is . In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post.

types of sheet metal pdf

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve.

electrical enclosure heater

The fundamental goal of sheet metal forming procedures is to give the metal sheets particular geometrical modifications while preserving their structural integrity. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here!There so many different types of metals that can be formed into sheets. Some examples are aluminum, steel, copper, tin, brass, etc., widely used in industries. Some precious metals, such as gold, silver, platinum are also used as sheet metals for special purposes.

Whether you’re in aerospace, automotive, or consumer electronics, understanding the various operations is vital for making informed manufacturing decisions. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each.In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a straight line across a strip, sheet, or bar. Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; Notching Operation; Bending Operation; 1). Sheet Metal Shearing Operations

In this article, we will discuss the various types of Sheet Metal Operations. But before moving ahead to understand these operations, we should also understand what actually the sheet metal is. Sheet Metal: Sheet Metal is a thin sheet produced by rolling or hammering.Gaining insight into the different types of sheet metal operations and their applications underscores the value of custom metal fabrication. This article delves into these operations, highlighting their significance and specific uses in the industry.Various manufacturing methods on sheet metals can be classified as follows: (a) Cutting and Shearing- Here the sheets are cut by using various tools. Blanking, piercing, perforation, notching etc. are various types of shearing operations. (b) Bending Operation- The sheet metals are straining around a straight axis. In this article, you will learn about 9 different types of Sheet Metal Operations with diagrams and you can also download the pdf file of this post.

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. The fundamental goal of sheet metal forming procedures is to give the metal sheets particular geometrical modifications while preserving their structural integrity. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here!There so many different types of metals that can be formed into sheets. Some examples are aluminum, steel, copper, tin, brass, etc., widely used in industries. Some precious metals, such as gold, silver, platinum are also used as sheet metals for special purposes.

Whether you’re in aerospace, automotive, or consumer electronics, understanding the various operations is vital for making informed manufacturing decisions. Read on and explore the different sheet metal operations to develop a comprehensive understanding of each.In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a straight line across a strip, sheet, or bar.

Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; Notching Operation; Bending Operation; 1). Sheet Metal Shearing Operations In this article, we will discuss the various types of Sheet Metal Operations. But before moving ahead to understand these operations, we should also understand what actually the sheet metal is. Sheet Metal: Sheet Metal is a thin sheet produced by rolling or hammering.Gaining insight into the different types of sheet metal operations and their applications underscores the value of custom metal fabrication. This article delves into these operations, highlighting their significance and specific uses in the industry.

Universal Junction Box UJB94-W KEY FEATURES: Compatible with Select ENS Security Cameras; Compatible Bracket Diameter Range: 2.4-3.7in (60-95mm) Easy Installation; Outdoor or Indoor junction box options; Made of Aluminum; Thread hole size: 3/4 inch((19mm) Specifications. Materials Aluminum; Size 3.7 x 1.7in (94 x 42mm) Weight 0.54lb (245g .

different sheet metal operations|shearing operation in sheet metal