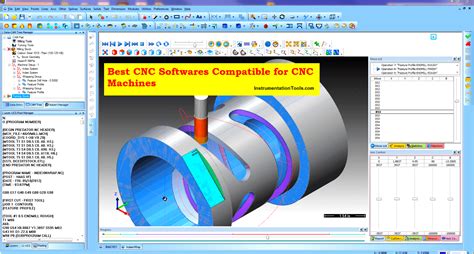

cnc machining design cad software The CAM software will convert the CAD design into G-code which is what the CNC machinerys speak. The G-code contains detailed information about the movement of the tool .

The Tuf-Tite B1 Riser is a square riser that can be attached to the top of your Tuf-Tite 4 Hole Distribution Box. This allows you to bring the lid up .

0 · programming software for cnc machines

1 · easiest cnc software for beginners

2 · cnc software for beginners

3 · cnc router software for beginners

4 · cnc milling machine programming software

5 · cnc machine software download

6 · cnc machine software 3 axis

7 · best cnc software for beginners

Our extensive line of hangers for plated truss connections are engineered to strengthen load-bearing connections in wood applications where trusses, beams or rafters are used.

Fusion is CAM software that can create high-quality CNC machining code for many types of CNC machine and NC controller. A subscription to Fusion includes free access to a library of .Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) . CNC design software (CAD) lets you create 2D or 3D CAD designs. CAM software for creates toolpaths and exports g-codes that your CNC router can interpret. CNC controller .Computer-Aided Design (CAD) software for CNC (Computer Numerical Control) machines is a type of program that helps engineers and designers create precise 3D models of parts and .

If Easel suits your purposes, you will have CAD software, CAM software, simulator software, and control software all in one place – ideal for beginners or hobbyists who want a .

The CAM software will convert the CAD design into G-code which is what the CNC machinerys speak. The G-code contains detailed information about the movement of the tool . A CAD-CAM software combines the functionality of both CAD and CAM to hasten the manufacturing process. Here are reviews of the best CAD/CAM software for CNC and guides to help you choose.

CAD/CAM software is a computer-aided design and manufacturing program for CNC machines, which helps users to do automatic CNC machining in industrial manufacturing. CAD makes designs more manageable and . Find 2024 best CAD/CAM software for designing & modeling with free & paid versions based on Windows, macOS. Review the most popular CNC software for machining.

programming software for cnc machines

CNC Machining needs to be paired with functional and reliable CAD and CAM software to produce high-quality parts. Learn more about the best CAD and CAM software here.Mastercam offers CAD/CAM software tools for a variety of CNC programming needs, from basic to complex. Due to our innovative, flexible solutions and top notch network of support, our software is a complete solution from the start of . The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

CAD/CAM software has revolutionized the manufacturing industry by streamlining the design and production process for CNC machines. CNC (Computer Numerical Control) machines use software to control the movement of tools and parts, .

This is where we need to use industrial design modeling software. Photo by Fakurian Design on Unsplash. In this article, we will take a look at the best of the best in industrial design modeling software for CNC solid modeling—Fusion 360, FreeCAD, SolidWorks, and SketchUp. Industrial Design Fusion 360

Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software. Design spur gears, escapements, ratchets, elliptical gears, heck design gears with arbitrary shapes that were imaginary, until you create them. Seriously cool features like point and click spoke design with hundreds of spoke patterns. Gear Simulation. Design a gear train and simulate how it will perform. CAD Output. DXF, 3D DXF, and STL’s .CAD, which stands for Computer-Aided Design, is the CNC software that lets you draw your designs. There are many CAD software packages out there, but unfortunately, most of them are not free. . Easel is a free CAD/CAM program that includes a machine controller for GRBL-based CNC machines. In that way, it's a complete CNC software package, as . SolidWorks, a 3D CAD software, is another noteworthy tool in the manufacturing industry.Its powerful features have made it popular among professionals seeking the best CAD/CAM software for CNC applications.. From the creation of intricate 3D models using its CAD programs for CNC to its ability to simulate real-world physics, SolidWorks offers a .

Mill-turn programming software is a type of computer-aided manufacturing (CAM) software designed for programming and controlling multi-axis mill-turn machines. Mill-turn machines are advanced machining centers that combine milling and turning capabilities in a single machine, allowing for the complete machining of complex parts in a single setup. 8 Best CAD/CAM Software for CNC Applications. Design processes for CAD and CAM are unique. Although they are part of the same manufacturing workflow, their process is quite different from each other. However, there is software capable of both undertaking CAD and CAM processes. Let us look at the best CAD/CAM software examples. 1. Fusion 360 CAD software – computer-aided design software is the first type of software you need to use to create your designs. CAM software – you then need computer-aided manufacturing software to convert your design into g-code and generate a toolpath for your router to follow. Many CNC router free software provide both CAD and CAM functionality.What is your favorite cad or vector software you use for cnc designs Share Add a Comment. Sort by: . With Fusion I have one program that does it all and being that I do CNC machining, 3d printing, laser engraving, circuit boards, and a little Carpentry I find I can design, solid model, machine, 3d print, engrave, and create technical drawings .

CAD-CAM software can provide you with the ability to undertake more complex 3-axis machining jobs.You can also add toolpath features to simplify multi-axis machining and increase its pace when working with 4 and 5 axis machines. A CAD-CAM system completely automates processes such as mold work while providing more toolpath choices for your part .This is where the magic happens - creating the tool paths that guide the machine's actions. Fusion 360, Mastercam, SolidWorks and BobCAM come into play here, allowing you to map out the manufacturing journey. Conversational. This type of programming software lets CNC machinists design tool paths for straightforward parts and shapes right at the .CAM software takes the CAD design and generates toolpaths and instructions for CNC (Computer Numerical Control) machines, 3D printers and other manufacturing equipment. It determines how to cut, shape or build the physical object based on the digital model. Every time you wish to create a design for CNC machining, you must first use CAD software. This makes design the first foundational stage. Machining operations are generally more expensive than other manufacturing .

In the world of CNC machining, the marriage of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software plays a pivotal role in driving efficiency, precision, and innovation.From conceptualization to the final product, CAD/CAM software streamlines the entire manufacturing process, revolutionizing the way we design and produce components.

Listed below are some key considerations for improving your CAD designs for CNC machining: Use the Right Software When designing parts for CNC machining, it’s best to use 3D modeling packages like SolidWorks ®, Inventor ®, NX™, or Solid Edge ®. These packages have many different features to streamline the CNC design process.

Advanced CAD software now incorporates CNC-specific features, allowing designers to simulate machining operations and optimize toolpaths directly within the design environment. Simultaneously, CAM systems are becoming more intuitive, with AI-driven algorithms that can automatically generate optimal cutting strategies based on the CAD model.Computer-aided manufacturing (CAM) software is used in design to produce prototypes and production parts. Using a software like Mastercam, parts that are created in design software are prepared for machining. The CAM software generates the toolpaths that control a CNC machine to cut or 3D print parts to the specifications of the design.Preparing for CNC Machining CAD Models. CNC machining starts with creating a CAD model, which is a computer-aided design of the intended part. A CAD model is created using specialized software, and it represents the geometric design of the object to be machined. These CAD files are essential in the CNC machining process, as they serve as the .

Autodesk Fusion software (formerly known as Fusion 360) provides professional-grade CAM tools to automate the programming of 2D, 2.5D, 3-, 4- and 5-axis CNC machinesSOLIDWORKS CAM Software uses rules-based machining to enhance the programming process while leveraging tolerances that were assigned to the component. . SOLIDWORKS CAM is an add-on to all versions of SOLIDWORKS CAD that lets you prepare your designs for manufacturability earlier in the development cycle. Manufacturing tasks that had to wait .

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values. . In the world of metalworking, the CAM part of CAD/CAM (computer-aided design/computer-aided manufacturing) generally means software for . CNC machines work alongside cutting-edge computer-assisted design (CAD) and computer-aided manufacturing (CAM) software to increase throughput and produce high-quality, repeatable results. The CNC machining market is estimated to be worth 0.78 billion globally by 2028 as exciting advancements like artificial intelligence (AI) streamline . Type3 Router8 is a professional CNC router software for computer-aided design (CAD), computer-aided manufacturing (CAM) to do 2D, 2.5D, 3D carving & cutting. Menu Toggle CNC Machines The CNC machine reads and follows the G-code instructions, performing the machining operations. In essence, CAM software serves as the bridge between a CAD design and the physical manufacturing process, ensuring that the CNC machine produces the desired part accurately and efficiently. Benefits of CAM Software for CNC Newcomers

china wall mount electric distribution box manufacturer

chinese mini cnc milling machine

Underbody Truck Tool Box Mounting Brackets Kit, Welded Formed Steel Mounting Brackets with Screws Spacers and Sleeves Bolts for Underbody Truck Bed Tool Box, 17.7X 17.7 Inch, Set of 2

cnc machining design cad software|best cnc software for beginners