bend sheet metal If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or .

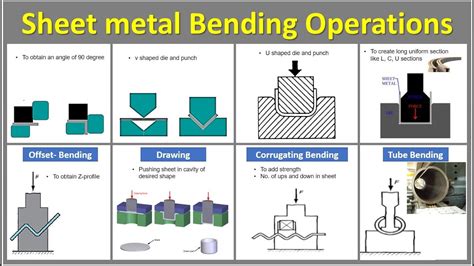

0 · types of sheet metal bends

1 · types of sheet metal benders

2 · sheet metal bending dies

3 · sheet metal bend tolerance chart

4 · sheet metal bend allowance chart

5 · maximum thickness sheet metal bending

6 · bend sheet metal at home

7 · bend allowance in sheet metal

An electrical sub panel is essentially a smaller version of the main panel. It acts as a secondary breaker box, distributing power to specific areas or appliances. Just like the main panel, it contains fuses and circuit breakers that protect .

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final .

wholesale china customized cnc parts price

Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and supplies. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

If you don’t have a special tool for bending sheet metal (called a “sheet metal brake”), you can also do it with a vise and your bare hands, provided that the metal isn’t too .

types of sheet metal bends

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----.

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and supplies.

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. If you don’t have a special tool for bending sheet metal (called a “sheet metal brake”), you can also do it with a vise and your bare hands, provided that the metal isn’t too thick. Below, we’ve outlined the basic materials and steps needed to bend metal for your own hobbies. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.-----. Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.

wholesale cnc machined milling parts

Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape. Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. Learn how to use a straight handle hand seamer to bend sheet metal. Learn about- -Sheet metal gauges -Types of hand seamers Sign up for the email list. Grab some great tools and supplies.

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

types of sheet metal benders

sheet metal bending dies

wholesale cnc machining bike parts

sheet metal bend tolerance chart

What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by .

bend sheet metal|types of sheet metal benders