are tension fittings required for junction boxes Boxes can be supported from a cord connected to fittings that prevent tension from being transmitted to joints or terminals [314.23(H)(1) and . Okuma has horizontal and vertical machining centers, including 5-axis machines, in a variety of sizes and configurations to meet any manufacturing needs.

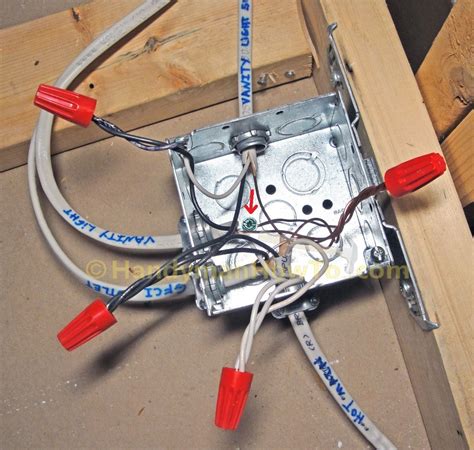

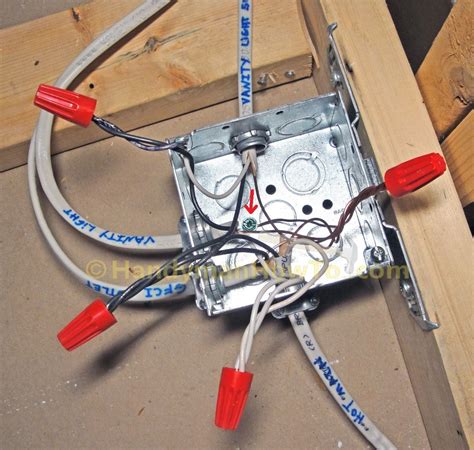

0 · wiring a junction box

1 · wire junction box installation

2 · nec junction box installation

3 · junction boxes above ceiling

4 · junction box installation instructions

5 · junction box above ceiling wiring

6 · how to install junction box above electrical

7 · ceiling junction box installation

Altelix Vented Enclosures are designed to help expel heat from within the enclosure. They are ideal for installations in high temperature environments or for use with equipment that generates high heat during operation.

All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box . Boxes can be supported from a cord connected to fittings that prevent tension from being transmitted to joints or terminals [314.23(H)(1) and .Junction boxes, with blank covers are allowed above a suspended ceiling as it is not considered a closed space. The wires that are loose and wirenuted need to be put in a j-box. Also, clamps need to be used at each wire going into a j-box.

Junction boxes must have the firm support necessary to prevent them from shifting or loosening. To ensure the stability of the junction box, you can install it with sturdy framing and clamps. Additionally, junction box covers must be .Unlike junction boxes and conduit bodies, terminal housings supplied with motors are not required to meet box fill requirements. Use 314.16 to determine the size box required for conductors 18 .

300.15 Boxes, Conduit Bodies, or Fittings — Where Required. A box shall be installed at each outlet and switch point for concealed knob-and-tube wiring. Fittings and connectors shall be .

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from .The box chosen must contain the proper fittings or connectors for the particular wiring method selected. For example, metal-clad cable (Type MC) must not be installed in a box specifically .All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy.

Boxes can be supported from a cord connected to fittings that prevent tension from being transmitted to joints or terminals [314.23(H)(1) and 400.10]. Covers. Each box must be provided with a cover or faceplate, unless it's covered by a fixture canopy, lampholder, or similar device [314.25].Junction boxes, with blank covers are allowed above a suspended ceiling as it is not considered a closed space. The wires that are loose and wirenuted need to be put in a j-box. Also, clamps need to be used at each wire going into a j-box. The NEC has outlined specific requirements for junction boxes to ensure the safety and proper installation of electrical wiring systems. Here are some of the requirements that your business will need to follow.Junction boxes must have the firm support necessary to prevent them from shifting or loosening. To ensure the stability of the junction box, you can install it with sturdy framing and clamps. Additionally, junction box covers must be tightened securely .

Unlike junction boxes and conduit bodies, terminal housings supplied with motors are not required to meet box fill requirements. Use 314.16 to determine the size box required for conductors 18 AWG through 6 AWG.

300.15 Boxes, Conduit Bodies, or Fittings — Where Required. A box shall be installed at each outlet and switch point for concealed knob-and-tube wiring. Fittings and connectors shall be used only with the specific wiring methods for which they are designed and listed. A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.The box chosen must contain the proper fittings or connectors for the particular wiring method selected. For example, metal-clad cable (Type MC) must not be installed in a box specifically designed for nonmetallic-sheathed cable.All pull boxes, junction boxes, and fittings shall be provided with covers. If metal covers are used, they shall be grounded. In energized installations each outlet box shall have a cover, faceplate, or fixture canopy.

All pull boxes, junction boxes, and fittings shall be provided with covers identified for the purpose. If metal covers are used, they shall be grounded. In completed installations, each outlet box shall have a cover, faceplate, or fixture canopy. Boxes can be supported from a cord connected to fittings that prevent tension from being transmitted to joints or terminals [314.23(H)(1) and 400.10]. Covers. Each box must be provided with a cover or faceplate, unless it's covered by a fixture canopy, lampholder, or similar device [314.25].Junction boxes, with blank covers are allowed above a suspended ceiling as it is not considered a closed space. The wires that are loose and wirenuted need to be put in a j-box. Also, clamps need to be used at each wire going into a j-box. The NEC has outlined specific requirements for junction boxes to ensure the safety and proper installation of electrical wiring systems. Here are some of the requirements that your business will need to follow.

Junction boxes must have the firm support necessary to prevent them from shifting or loosening. To ensure the stability of the junction box, you can install it with sturdy framing and clamps. Additionally, junction box covers must be tightened securely .Unlike junction boxes and conduit bodies, terminal housings supplied with motors are not required to meet box fill requirements. Use 314.16 to determine the size box required for conductors 18 AWG through 6 AWG.

300.15 Boxes, Conduit Bodies, or Fittings — Where Required. A box shall be installed at each outlet and switch point for concealed knob-and-tube wiring. Fittings and connectors shall be used only with the specific wiring methods for which they are designed and listed.

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

light blue house with cream trim with metal roof

wiring a junction box

wire junction box installation

We have updated our product approvals and installation instructions for the 2020 Florida Building Code, which is effective beginning January 1, 2021.Vernon Steel Inc., a locally owned steel provider, is large enough to fulfill steel orders of any size, anywhere, yet small enough to offer personal service to all our customers. Contact us for .

are tension fittings required for junction boxes|junction box installation instructions