cnc machine for countertop The TITAN® Fab Center combines efficient sawing and accurate edging capabilities in one machine. With just 2 employees working an 8-hour shift, you can produce 120 square .

Airtight and safe, these eco-friendly lunch boxes store your food in healthy, plastic-free and zero-waste way. Available in 4 sizes to divide your meals, e.g. 1 for the snacks, 1 for the soup or rice, 1 for your entree and 1 for your fruits. Made with food .

0 · industrial stone cutting machine

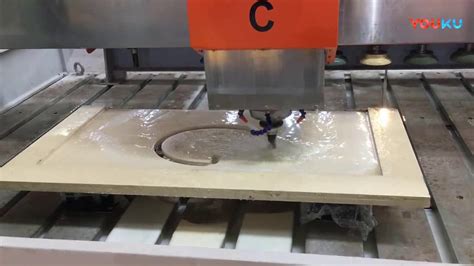

1 · granite sink cutout machine

2 · granite countertop cnc machine

3 · granite cnc machines for sale

4 · cnc machines for stone carving

5 · cnc machine for granite cutting

6 · cnc for stone countertops

7 · automatic stone cutting machine

Choose from our standard bolt plate connections, aluminum fork ends (spigots) or high strength plated steel fork end (spigot) connections depending on the strength and load rating required for your project. Below are some XSF Box Trussing Options we offer.

Learn More About the Park Industries® TITAN® CNC Router, the Leading Stone Center for Edge Polishing and Finishing Stone Countertops. Contact Park Industries® Now!

The TITAN® Fab Center combines efficient sawing and accurate edging capabilities .

industrial stone cutting machine

granite sink cutout machine

Park Industries is a Manufacturer of Stone CNC machinery for fabricators across .Park Industries is a Manufacturer of Stone CNC machinery for fabricators across North America. Browse USA made equipment!Countertop Fabrication CNC Machines - Countertops are created from granite, quartz & marble. Omni CNC router machines are ideally suited for countertop production. The TITAN® Fab Center combines efficient sawing and accurate edging capabilities in one machine. With just 2 employees working an 8-hour shift, you can produce 120 square .

5 axis CNC bridge saw is an automatic infrared stone cutter to make custom slabs and countertops for kitchen and bath including granites, modular granites, granite tiles, honed .CNC Stone Router. This one-machine solution exceeds the challenging needs of most contemporary stone fabricators. A large work envelope up to 15 ft. x 8 ft. allows your operator to process an entire slab worth of countertops in one setup. A 5-axis CNC (Computer Numerical Control) saw for the stone industry is a highly advanced machine used for cutting, shaping, and processing stone materials, such as marble, granite, and other natural or engineered stones.OMNI cnc stone carving machine, designed for tomb carving, sink, pillar, fireplace, countertop, architecture decoration. Upgrade your fabrication today.

A Virginia-based state-of-the-art facility has deployed two of these powerful CNT stone fabrication CNC machines for high-precision stone countertop and mantle production. This machine holds 30 tools (15 on-the-fly; 15 rack-mounted) and . Choosing a CNC machine for stone is crucial to production efficiency and finished product quality. Here are 8 of the best CNC machines for stone. Bridge saw CNC machines for stone cutting are specialized tools used . Learn More About the Park Industries® TITAN® CNC Router, the Leading Stone Center for Edge Polishing and Finishing Stone Countertops. Contact Park Industries® Now!

Park Industries is a Manufacturer of Stone CNC machinery for fabricators across North America. Browse USA made equipment!Countertop Fabrication CNC Machines - Countertops are created from granite, quartz & marble. Omni CNC router machines are ideally suited for countertop production.The TITAN® Fab Center combines efficient sawing and accurate edging capabilities in one machine. With just 2 employees working an 8-hour shift, you can produce 120 square feet of finished countertops with the TITAN Fab Center. Cut, miter, shape, and polish all on one machine.

5 axis CNC bridge saw is an automatic infrared stone cutter to make custom slabs and countertops for kitchen and bath including granites, modular granites, granite tiles, honed granites, engineered stones, laminates, soapstones, marbles, quartzites and other stones.CNC Stone Router. This one-machine solution exceeds the challenging needs of most contemporary stone fabricators. A large work envelope up to 15 ft. x 8 ft. allows your operator to process an entire slab worth of countertops in one setup. A 5-axis CNC (Computer Numerical Control) saw for the stone industry is a highly advanced machine used for cutting, shaping, and processing stone materials, such as marble, granite, and other natural or engineered stones.OMNI cnc stone carving machine, designed for tomb carving, sink, pillar, fireplace, countertop, architecture decoration. Upgrade your fabrication today.

granite countertop cnc machine

A Virginia-based state-of-the-art facility has deployed two of these powerful CNT stone fabrication CNC machines for high-precision stone countertop and mantle production. This machine holds 30 tools (15 on-the-fly; 15 rack-mounted) and has a 72″ X 168″ cutting area. Choosing a CNC machine for stone is crucial to production efficiency and finished product quality. Here are 8 of the best CNC machines for stone. Bridge saw CNC machines for stone cutting are specialized tools used in the stone fabrication industry. Learn More About the Park Industries® TITAN® CNC Router, the Leading Stone Center for Edge Polishing and Finishing Stone Countertops. Contact Park Industries® Now!Park Industries is a Manufacturer of Stone CNC machinery for fabricators across North America. Browse USA made equipment!

Countertop Fabrication CNC Machines - Countertops are created from granite, quartz & marble. Omni CNC router machines are ideally suited for countertop production.The TITAN® Fab Center combines efficient sawing and accurate edging capabilities in one machine. With just 2 employees working an 8-hour shift, you can produce 120 square feet of finished countertops with the TITAN Fab Center. Cut, miter, shape, and polish all on one machine.

5 axis CNC bridge saw is an automatic infrared stone cutter to make custom slabs and countertops for kitchen and bath including granites, modular granites, granite tiles, honed granites, engineered stones, laminates, soapstones, marbles, quartzites and other stones.

CNC Stone Router. This one-machine solution exceeds the challenging needs of most contemporary stone fabricators. A large work envelope up to 15 ft. x 8 ft. allows your operator to process an entire slab worth of countertops in one setup. A 5-axis CNC (Computer Numerical Control) saw for the stone industry is a highly advanced machine used for cutting, shaping, and processing stone materials, such as marble, granite, and other natural or engineered stones.OMNI cnc stone carving machine, designed for tomb carving, sink, pillar, fireplace, countertop, architecture decoration. Upgrade your fabrication today.A Virginia-based state-of-the-art facility has deployed two of these powerful CNT stone fabrication CNC machines for high-precision stone countertop and mantle production. This machine holds 30 tools (15 on-the-fly; 15 rack-mounted) and has a 72″ X 168″ cutting area.

granite cnc machines for sale

cnc machines for stone carving

cnc machine for granite cutting

cnc for stone countertops

See the Universal ST-314-48, 14" X 48" stainless steel storage cabinet with two .

cnc machine for countertop|cnc machine for granite cutting