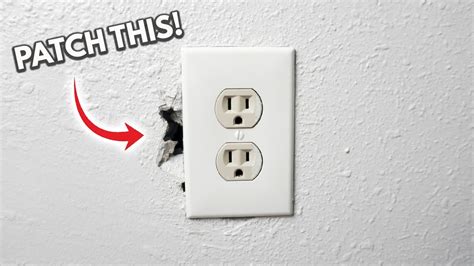

electrical box screw stripped There are a few options for repairing a broken screw hole in a plastic electrical box. My standard choice was to replace the electrical box. The G-Clip gives me the option to repair it if possible. Explore a world of possibilities for your kitchen or workspace with our versatile stainless steel base cabinets. Tailored to meet your specific needs, our collection boasts a variety of sizes, ensuring you find the perfect fit for your requirements.

0 · repair broken electrical outlet box

1 · outlet box screw hole broken

2 · loose electrical box in wall

3 · how to remove outlet box

4 · electrical outlet box repair clips

5 · electrical box screw hole broken

6 · broken screw in electrical box

7 · broken electrical outlet box

Industrial Enclosures, Sheet Metal Fabrication, & Custom Kiosks. Gamlet's has innovative products, competitive costs, and superior service.

Given that the box is plastic, you have at least 3 options: Try a slightly larger screw. Fill the mounting hole(s) in the box with epoxy, drill a new . In a couple of rooms there are outlets with stripped screws so that they are not secured to the junction box anymore. Instead of opening up the wall and replacing the box, it's .There are a few options for repairing a broken screw hole in a plastic electrical box. My standard choice was to replace the electrical box. The G-Clip gives me the option to repair it if possible. How to Fix a Screwy Electrical Box. I recently had to deal with a loose receptacle inside a plastic electrical box. It turned out the screw holes in .

Either the person installing it stripped the head as they installed it or the head is still intact but it is so frozen by rust or other issues it won’t budge. This is common in door hinge. A previous owner of my house (I swear it was not me :) ) appears to have broken off a screw in the hole (red circle) that allows the bottom of the outlet to attach to the box, leaving only the top hole (yellow circle) free to .

Without having to replace the electrical box itself, is there a quick fix to be able to screw the outlet into the box? Get bigger screws, or get a tap set that is small enough to retap the screw hole. ...... Answers based on the . I am in the process of replacing electrical outlets in my newly purchased home (wife wanted white instead of cream). In the process I have found several that have the hole where the screw goes into the electrical box broken not allowing me the screw the outlet into the box. When I went to attach the bracket to the electrical box, one screw was fine, but the other hole was stripped. When I climbed in the attic to check how the box was mounted to see if it could be easily changed, it's nailed to the beam and going to be difficult to remove. A friend mentioned rethreading the hole. Whats the best way to fix this?

I've used a torx type screw tip on occasions. Find one that fits and tap it in with a few good wacks. Try getting it out first by hand (low torque), a power drill (high torque) will continue to damage the screw head. The hacksaw or Sawzall methods would be the next step. Used galvanized, or any other screw rated for exterior use. On my electrical box for the ceiling light fixture it has two screw holes (8-32) to hang the weight of the fixture. The electrical box seems like a type of hard plastic but the screw holes are metal threads. It seems like a very old box. One of the holes is stripped. Would tapping it with a 10-32 tap (using tap wrench) do the trick?

The other screw on the bottom of the box will keep the plug from moving around. Cut off the excess wire to allow the plate to fit over the plug. I'd be cautious to will the broken screw hole with anything that will not allow you to remove . Separate issue -One of the six panel cover screw holes is stripped. Seems like there are a few ways to fix this that are somewhat controversial (next larger screw, screw clip, etc.). Is there a method that's both safe and generally accepted by inspectors? I could try to re-tap, but are the odds favorable if it's already stripped? Thanks. The 2 horizontal screws weren't flush to the sconce metal plate, so I tried to adjust them and screw them in tighter. This was when I found that the screws were barely holding anything, because the plastic screw holes were cracked and the screws could easily be pulled out. Just for an example, the mounting box looks sort of like this.

If the 10-32 screw is stripped out then the next size you can use is 1/4-20 but you may want to tap it first. By the way 10-32 is the same screw you will find with green grounding screw which you will see in the junction box. Merci, Marc Yes, they can work. But, I hate it when EZ outs and/or their drill bits break and stay in the hole after the bit travels off-center and binds when the bracket vs the bolt shaft vs the ceiling box dogear are encountered. The nut is an option. I have worked with licensed electricians, that take the insulation that they removed from the wires , when hooking up the device ( outlet / switch ), and inserting the device screw into the stripped insulation, the length needed to make the device stand proud of the box, just enough to be flush with the paneled surface.

I am in the process of replacing electrical outlets in my newly purchased home (wife wanted white instead of cream). In the process I have found several that have the hole where the screw goes into the electrical box broken not allowing me the screw the outlet into the box. When I went to attach the bracket to the electrical box, one screw was fine, but the other hole was stripped. When I climbed in the attic to check how the box was mounted to see if it could be easily changed, it's nailed to the beam and going to be difficult to remove. A friend mentioned rethreading the hole. Whats the best way to fix this? I've used a torx type screw tip on occasions. Find one that fits and tap it in with a few good wacks. Try getting it out first by hand (low torque), a power drill (high torque) will continue to damage the screw head. The hacksaw or Sawzall methods would be the next step. Used galvanized, or any other screw rated for exterior use. On my electrical box for the ceiling light fixture it has two screw holes (8-32) to hang the weight of the fixture. The electrical box seems like a type of hard plastic but the screw holes are metal threads. It seems like a very old box. One of the holes is stripped. Would tapping it with a 10-32 tap (using tap wrench) do the trick?

The other screw on the bottom of the box will keep the plug from moving around. Cut off the excess wire to allow the plate to fit over the plug. I'd be cautious to will the broken screw hole with anything that will not allow you to remove .

Separate issue -One of the six panel cover screw holes is stripped. Seems like there are a few ways to fix this that are somewhat controversial (next larger screw, screw clip, etc.). Is there a method that's both safe and generally accepted by inspectors? I could try to re-tap, but are the odds favorable if it's already stripped? Thanks. The 2 horizontal screws weren't flush to the sconce metal plate, so I tried to adjust them and screw them in tighter. This was when I found that the screws were barely holding anything, because the plastic screw holes were cracked and the screws could easily be pulled out. Just for an example, the mounting box looks sort of like this.

If the 10-32 screw is stripped out then the next size you can use is 1/4-20 but you may want to tap it first. By the way 10-32 is the same screw you will find with green grounding screw which you will see in the junction box. Merci, Marc Yes, they can work. But, I hate it when EZ outs and/or their drill bits break and stay in the hole after the bit travels off-center and binds when the bracket vs the bolt shaft vs the ceiling box dogear are encountered.

repair broken electrical outlet box

metal houses

metal house siding omaha

Precision CNC Machining Parts Service & Custom CNC Machined Parts Manufacturer. Bergek CNC is good at making prototypes, small-batch, or mass-production customized CNC machined parts. Come to get instant quotes on metal and plastic machined parts.Global Precision Parts, Inc. is the strategic global leader in precision machined parts. We excel not only in our precision machining services, but also value-added customer services such as .

electrical box screw stripped|how to remove outlet box