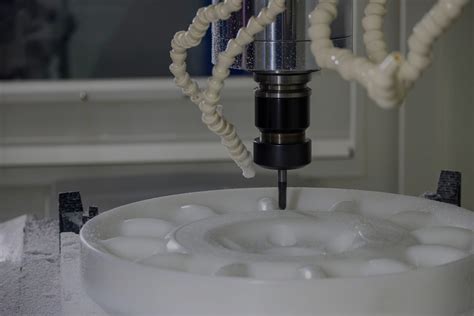

cnc machine plastic molding Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment does this by controlling the tools that cut plastic materials very precisely so as .

“STD” denotes standard (nonvariable volume) air duct construction requirements (regardless of actual velocity level) for compliance with this document for all cases in which the designer does not designate the pressure classification for the duct system independent of fan static rating.

0 · plastic for cnc milling

1 · plastic cnc machining near me

2 · lowest price cnc plastic machining

3 · cnc router for plastic sheets

4 · cnc plastic cutting near me

5 · cnc machine for plastic products

6 · cnc machine for plastic cutting

7 · best plastic for cnc milling

If the box was not grounded, it will pick up ground from the outlet while the outlet is bolted to it. If a hot wire touched the metal box it would trip the breaker. That's a code violation because if the outlet is removed, the box loses the ground, so it can introduce hazard in some more complex circuits - probably not here.

plastic for cnc milling

CNC machining and plastic injection molding are two very different, yet equally successful ways to produce parts. Learn about the similarities and differences between CNC machining and plastic injection . CNC machining creates the desired part by removing the material with cutting tools. In contrast, the injection molding method involves injecting the molten material into a mold that contains negative geometry of the desired .

is illegal to weld sheet metal to a truck

Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, . Key Considerations for CNC Machining vs. Injection Molding. The plastic injection molding process involves heating pellets of thermoplastic resin, injecting the molten material into a hardened steel mold through a pressurized . CNC machining and plastic injection molding both allow you to make parts quickly and accurately, but these processes are quite distinct from each other and have varying use .

Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment does this by controlling the tools that cut plastic materials very precisely so as .CNC plastic machining is a subtractive manufacturing process that uses computer-controlled tools to shape plastic materials. This method offers precision, efficiency, and versatility, making it ideal for creating complex and high-quality .

In the dynamic world of plastic fabrication, two primary technologies stand out in the manufacturing of plastic parts: CNC Machining and Injection Molding. Each method boasts unique strengths and applications, making them go-to choices . CNC machining plastic is much different from injection molding, so understanding the processes, as well as the advantages and limitations of each, can help you decide which manufacturing process is best suited to your . CNC plastic machining and injection molding both are extremely popular with manufacturers, and each is suitable for certain applications based on their strengths. Read the following points of comparison to understand it better.

CNC machining and plastic injection molding are two very different, yet equally successful ways to produce parts. Learn about the similarities and differences between CNC machining and plastic injection molding. CNC machining creates the desired part by removing the material with cutting tools. In contrast, the injection molding method involves injecting the molten material into a mold that contains negative geometry of the desired shape. Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, subtracts material through cutting and drilling to achieve the desired form. Key Considerations for CNC Machining vs. Injection Molding. The plastic injection molding process involves heating pellets of thermoplastic resin, injecting the molten material into a hardened steel mold through a pressurized nozzle, ejecting the part once it .

CNC machining and plastic injection molding both allow you to make parts quickly and accurately, but these processes are quite distinct from each other and have varying use cases. So, it’s vital to consider which manufacturing . Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment does this by controlling the tools that cut plastic materials very precisely so as to take shape into what is desired.CNC plastic machining is a subtractive manufacturing process that uses computer-controlled tools to shape plastic materials. This method offers precision, efficiency, and versatility, making it ideal for creating complex and high-quality parts.In the dynamic world of plastic fabrication, two primary technologies stand out in the manufacturing of plastic parts: CNC Machining and Injection Molding. Each method boasts unique strengths and applications, making them go-to choices for manufacturers worldwide.

CNC machining plastic is much different from injection molding, so understanding the processes, as well as the advantages and limitations of each, can help you decide which manufacturing process is best suited to your project or if both are needed. This guide explores the two techniques. CNC plastic machining and injection molding both are extremely popular with manufacturers, and each is suitable for certain applications based on their strengths. Read the following points of comparison to understand it better. CNC machining and plastic injection molding are two very different, yet equally successful ways to produce parts. Learn about the similarities and differences between CNC machining and plastic injection molding.

CNC machining creates the desired part by removing the material with cutting tools. In contrast, the injection molding method involves injecting the molten material into a mold that contains negative geometry of the desired shape. Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, subtracts material through cutting and drilling to achieve the desired form. Key Considerations for CNC Machining vs. Injection Molding. The plastic injection molding process involves heating pellets of thermoplastic resin, injecting the molten material into a hardened steel mold through a pressurized nozzle, ejecting the part once it . CNC machining and plastic injection molding both allow you to make parts quickly and accurately, but these processes are quite distinct from each other and have varying use cases. So, it’s vital to consider which manufacturing .

Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment does this by controlling the tools that cut plastic materials very precisely so as to take shape into what is desired.CNC plastic machining is a subtractive manufacturing process that uses computer-controlled tools to shape plastic materials. This method offers precision, efficiency, and versatility, making it ideal for creating complex and high-quality parts.In the dynamic world of plastic fabrication, two primary technologies stand out in the manufacturing of plastic parts: CNC Machining and Injection Molding. Each method boasts unique strengths and applications, making them go-to choices for manufacturers worldwide. CNC machining plastic is much different from injection molding, so understanding the processes, as well as the advantages and limitations of each, can help you decide which manufacturing process is best suited to your project or if both are needed. This guide explores the two techniques.

plastic cnc machining near me

lowest price cnc plastic machining

iron sheet metal home depot

cnc router for plastic sheets

Yes, you can glue fabric to metal. Using the right adhesive and proper application techniques, it’s possible to create a strong bond between fabric and metal surfaces. The process involves preparing the metal surface by cleaning and, if needed, roughening it for better adhesion.

cnc machine plastic molding|plastic cnc machining near me