cnc machine coolant mixer FlexxCool eliminates up to 80% of CNC coolant-related issues. WHAT CAN . CNC machines, or Computer Numerical Control machines, are manufacturing marvels that integrate accuracy, speed, and regularity based on computerized systems. The .

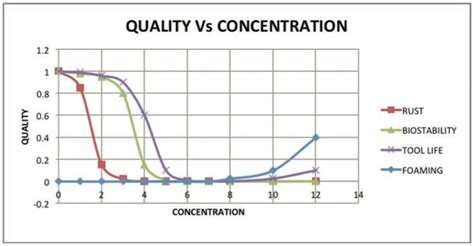

0 · machine coolant concentration chart

1 · how to maintain machine coolant

2 · coolant mixers for cnc equipment

3 · coolant concentration mixer

4 · coolant chiller for cnc

5 · cnc coolant recycling system

6 · blaser jet mix coolant mixer

7 · 55 gallon drum coolant mixer

24-gauge and 26-gauge steel (Galvalume®) are common material thicknesses throughout the metal roofing industry — but which one is the better choice for your home or property? By: Julianne Calapa | Posted on February 2, 2023

Increasing efficiency with coolant automation. FlexxCool’s automated CNC coolant system mixes & delivers coolant, monitors sump levels, and controls concentration.

STOP WASTING TIME AND MONEY FILLING COOLANT MANUALLY. .FlexxCool eliminates up to 80% of CNC coolant-related issues. WHAT CAN .Automation is already an important part of the manufacturing industry. Introducing .As an innovator in automated coolant processing, FlexxCool is at the forefront .

About Us A GROUND-BREAKING CNC MACHINE COOLANT SYSTEM. .

machine coolant concentration chart

how to maintain machine coolant

FlexxCool’s automated coolant filling system is the next step in CNC machine .Support Need Customer Support? Our FlexxCool products are backed by .Although each shop is different (size, shifts, machines), every FlexxCool customer .Dazzle™ 2 utilizes a precision mixing algorithm that automatically mixes neat coolant and water to the precise target make-up concentration for each machine sump. Set concentration, set sump high and low levels: done.

FlexxCool’s automated coolant filling system is the next step in CNC machine automation. Designed by a machine shop for machine shops, it helps recover labor hours, increases .With the modular Dazzle™ 1 or the cutting-edge, Industry 4.0-compliant Dazzle™ 2, you can effortlessly fully automate your coolant mixing, concentration, delivery, and sump levels. Enjoy a shop-proven ROI within just 8 months, up to 80% in .Introducing the world’s most advanced coolant mixers that are virtually maintenance free, highly accurate, and provide easy and fast adjustment. Groz coolant mixers use a rotary disc valve .

National Machine Products offers coolant management systems from Dosing & Pumps, which provide real-time analysis and control of industrial liquids. These systems enhance efficiency, reduce downtime, and minimize waste, ensuring .FlexxCool eliminates up to 80% of CNC coolant-related issues. WHAT CAN FLEXXCOOL HELP YOU DO? Stop lugging buckets of coolant from machine to machine. FlexxCool keeps each machine full and at the correct concentrate % .

coolant mixers for cnc equipment

Find the best coolant dispensers and mixing stations for your CNC sumps. Easily create the perfect coolant blend for optimal machine performance.Coolant Management Solution Scalable filling, mixing and control for up to 120 CNC

Increasing efficiency with coolant automation. FlexxCool’s automated CNC coolant system mixes & delivers coolant, monitors sump levels, and controls concentration.From its sophisticated operating system to its UTC-patented mixing process and advanced machine coolant and concentrate level monitoring, it offers the newest – and best – way to automatically fill sumps with coolant.Stop lugging buckets of coolant from machine to machine. FlexxCool keeps each machine full and at the correct concentrate % automatically, so your team can focus on more valuable tasks than filling coolant.We have built a CNC machine coolant system that delivers unparalleled savings, efficiency, and performance. Once we developed the first iteration of FlexxCool, we discovered that by keeping our machines always full and at the right concentration, all of our other coolant issues went away.

14 sheet metal thickness

FlexxCool, a leader in advanced coolant management solutions, offers customizable systems that cater to the diverse needs of various CNC applications, from high-speed milling to precision turning. This article delves into the importance of tailored coolant solutions and how FlexxCool is setting new standards in the industry. By automating coolant delivery, our system enhances the capabilities of modern CNC machines, supporting the production of high-quality components efficiently and sustainably. Embrace the next level of CNC machining precision with . FlexxCool’s automated system monitors your CNC machine’s concentration levels and keeps them consistent. Ensuring that you get the most out of your preferred coolant. NEVER LOSEAutomating coolant filling optimizes CNC machine maintenance so that you can focus on manufacturing parts instead of maintaining machines. Here are just a few examples of how we have helped manufacturers.

Automation is already an important part of the manufacturing industry. Introducing robots to achieve lights-out machining is a game-changer until they run out of coolant in the middle of the night. FlexxCool keeps machine sumps full automatically, allowing uninterrupted machining up-time through CNC coolant automation. The FlexxCool system features automated processes that monitor your machine’s coolant levels and top-up or refills according to the machine’s needs, alleviating the time needed to do it manually and ensuring that the second shift never comes into an “empty tank”.Increasing efficiency with coolant automation. FlexxCool’s automated CNC coolant system mixes & delivers coolant, monitors sump levels, and controls concentration.

From its sophisticated operating system to its UTC-patented mixing process and advanced machine coolant and concentrate level monitoring, it offers the newest – and best – way to automatically fill sumps with coolant.Stop lugging buckets of coolant from machine to machine. FlexxCool keeps each machine full and at the correct concentrate % automatically, so your team can focus on more valuable tasks than filling coolant.

We have built a CNC machine coolant system that delivers unparalleled savings, efficiency, and performance. Once we developed the first iteration of FlexxCool, we discovered that by keeping our machines always full and at the right concentration, all of our other coolant issues went away.FlexxCool, a leader in advanced coolant management solutions, offers customizable systems that cater to the diverse needs of various CNC applications, from high-speed milling to precision turning. This article delves into the importance of tailored coolant solutions and how FlexxCool is setting new standards in the industry. By automating coolant delivery, our system enhances the capabilities of modern CNC machines, supporting the production of high-quality components efficiently and sustainably. Embrace the next level of CNC machining precision with . FlexxCool’s automated system monitors your CNC machine’s concentration levels and keeps them consistent. Ensuring that you get the most out of your preferred coolant. NEVER LOSE

Automating coolant filling optimizes CNC machine maintenance so that you can focus on manufacturing parts instead of maintaining machines. Here are just a few examples of how we have helped manufacturers.Automation is already an important part of the manufacturing industry. Introducing robots to achieve lights-out machining is a game-changer until they run out of coolant in the middle of the night. FlexxCool keeps machine sumps full automatically, allowing uninterrupted machining up-time through CNC coolant automation.

coolant concentration mixer

Before CNC existed, there was only NC. This means Numerical Control (without the “C” of Computer), where back in the 1950s punched tape was used to manually input commands on to data cards to describe where to move the machine and tools to cut parts. This was . See more

cnc machine coolant mixer|coolant concentration mixer