diy cnc lathe machine This is a short video about how to make a homemade CNC Metal Lathe. It took me about 5-6 months doing it in free time. There was a lot to improve and many things didn't work at the begining.

What type of wiring methods do you normally install/accept in walk-in coolers & freezers (Restaurant/grocery facilities) ? The majority I see are wired with EMT, but I see a mix .

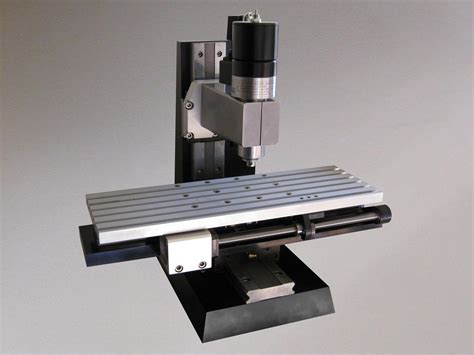

0 · make your own cnc mill

1 · homemade cnc milling machine plans

2 · homemade cnc machine plans

3 · diy cnc mill kit cost

4 · cool cnc lathe projects

5 · cnc lathe conversion kit

6 · build your own cnc mill

7 · build your own cnc lathe

For example, 16-gauge steel is approximately 1.52 mm thick, while 16-gauge aluminum is about 1.29 mm. Importance of Verification: Always confirm the precise thickness with your material supplier, particularly for polished, coated, or heat-treated materials.

To build a high-quality homemade CNC lathe machine, it's crucial to select the right components. In this section, we will guide you through choosing a suitable spindle, stepper motors, linear .

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.

When learning how to build a CNC lathe, understanding the essential parts and requirements is crucial. Here’s a summary to get you started: Mechanical Structure: Sturdy bed, headstock, tailstock, carriage, and tool post. .I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes . Building The 5-Axis CNC Machine in a Small Room: A DIY Journey. #DIY #CNC #5axis #Awesome_CNC_Freek How to make a DIY CNC Lathe series digest. I had always .

This is a short video about how to make a homemade CNC Metal Lathe. It took me about 5-6 months doing it in free time. There was a lot to improve and many things didn't work at the begining.To build a high-quality homemade CNC lathe machine, it's crucial to select the right components. In this section, we will guide you through choosing a suitable spindle, stepper motors, linear guides, electronics, and control software.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.When learning how to build a CNC lathe, understanding the essential parts and requirements is crucial. Here’s a summary to get you started: Mechanical Structure: Sturdy bed, headstock, tailstock, carriage, and tool post. Electronics: Motors, controllers, actuators, and a .

make your own cnc mill

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine. Building The 5-Axis CNC Machine in a Small Room: A DIY Journey. #DIY #CNC #5axis #Awesome_CNC_Freek How to make a DIY CNC Lathe series digest. I had always wanted a CNC lathe to.site: https://www.FishersShopOnline.comPlans: https://www.FishersShopOnline.com/plansInstagram: https://www.Instagram.com/fishersshopStore: https://www.Am.

homemade cnc milling machine plans

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.While seaching for ideas I came across some plan to do a simply cnc conversion to a C1, C2, C3 mini lathe. From the website. The C2 Mini lathe kit was designed specifically for the mini lathe that many tool resellers sell including Harbor Freight, Grizzly, Homier, and many more.

IndyMill is a project started by Nikodem Bartnik as an upgrade of Dremel CNC machine. The basic idea behind this project is to create easy to build CNC machine that anyone around the world can reproduce. Using popular, easily available components is only . This is a short video about how to make a homemade CNC Metal Lathe. It took me about 5-6 months doing it in free time. There was a lot to improve and many things didn't work at the begining.

To build a high-quality homemade CNC lathe machine, it's crucial to select the right components. In this section, we will guide you through choosing a suitable spindle, stepper motors, linear guides, electronics, and control software.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled.When learning how to build a CNC lathe, understanding the essential parts and requirements is crucial. Here’s a summary to get you started: Mechanical Structure: Sturdy bed, headstock, tailstock, carriage, and tool post. Electronics: Motors, controllers, actuators, and a .

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine. Building The 5-Axis CNC Machine in a Small Room: A DIY Journey. #DIY #CNC #5axis #Awesome_CNC_Freek How to make a DIY CNC Lathe series digest. I had always wanted a CNC lathe to.site: https://www.FishersShopOnline.comPlans: https://www.FishersShopOnline.com/plansInstagram: https://www.Instagram.com/fishersshopStore: https://www.Am.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.While seaching for ideas I came across some plan to do a simply cnc conversion to a C1, C2, C3 mini lathe. From the website. The C2 Mini lathe kit was designed specifically for the mini lathe that many tool resellers sell including Harbor Freight, Grizzly, Homier, and many more.

how to mount an electrical box between studs

homemade cnc machine plans

So if you want to metal detect at old house sites, and are willing to travel, then head over to Boston to have a great time searching through years of history. The median age of houses in Boston is 110 years, while the median year built for homes is 1910.

diy cnc lathe machine|homemade cnc milling machine plans