how to make a sheet metal offset Our Transitional elbow will be offset from one side only. Here you will layout a 90 Deg. elbow 8/12 to 8/10 keeping one side straight. Draw your flat side pattern and bisect the heel and throat curves, establishing points 3 & 6.

You will find the sythetic steel wool pads virtually anywhere that paint is sold. 3-M is fine. Grey is about 000 grade steel wool. To get bronze wool I'd bet you would have to drive to one of the coasts where it might be used by the marine trade.

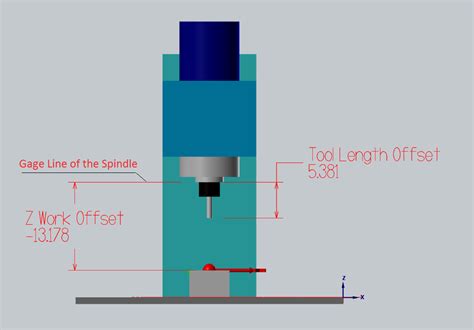

0 · offset tool depth

1 · offset bends sheet metal

2 · how to offset sheet metal

3 · how to offset material

4 · how to make offset geometry

5 · how to make offset bends

6 · how to form offsets

7 · horizontal offset tool

Ford does refer to it as the Smart Junction Box in the TSB and in the Ford Service Manual Wiring Diagrams.

offset tool depth

In this video I'll detail how to make an offset in sheet metal so you can overlap 2 panels together. I'll show how to use your hammer and dollies and also how to use a set of offset.

Yes, Approved Sheet Metal not only provides standard offset gaps for designing bends but also offers assistance in calculating and creating offsets specific to your needs. You can request a quote from them for your offset bend . Learn how to create sheet metal fabricated parts with our free online tutorials. Sheet Metal Offsets. Sheet metal offsets help your designs by allowing for layering of parts within the same application. Learn more in our related blog post:.

2 circuits in one junction box

offset bends sheet metal

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.

Our Transitional elbow will be offset from one side only. Here you will layout a 90 Deg. elbow 8/12 to 8/10 keeping one side straight. Draw your flat side pattern and bisect the heel and throat curves, establishing points 3 & 6.DESIGN TIPS. OFFSET. Whenever possible, maintain minimum spacing of 2-2.5x raw material thickness from edge of cutout to bend radius tangency. Lesser spacing requires secondary . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a .Offset bending can be used to form two equal and opposite bends that are too close together for regular bending. Offset bends can be used to create a flat surface when connecting two panels, or to strengthen the sheet metal.

The offset process in sheet metal is bending a sheet metal workpiece in an equipment unit or offset bender. Bend the metal by 20° to 30° using the formers. Release the part, turn it over, and joggle sheet metal to .

-- Truewerk Workwear --https://www.truewerk.com/zac15 (Use promo code "ZAC15" to save 15%)— SUPPORT THE CHANNEL —https://www.patreon.com/qualityhvacr?fan_lan. HerrTick wrote: ↑ Tue Nov 02, 2021 1:02 pm There's an persistent and pernicious dogma in CAD (not just SW) that sheet metal parts must consist of only sheet metal features from the sheet metal app. Utter tosh! Z-bends (including jogs) are a great reason to ditch this dogma. In many cases, it is far simpler and better for the design (you know, the thing that matter most) to . This time at the Quick Speed Shop I'm going to show you a simple method you can use to make any kind of flat sheet metal patch panel for rust repair on your .

Hey guys in this video, I demonstrate how to perform a offset with duct board. I hope this video is informative , also please like and subscribe.https://shar. Don't just tape pieces together for your duct transitions! Joe walks you through how to build a proper sheet metal duct transition so all of your jobs look p.I found out how to do this by asking some men who were experienced in sheet metal work. Here is how it is done: make all the corner cutouts. score the end flap [4] and [5] creases with a sharp knife. bend down the end flaps, [4] and [5] using the brake

2 gang outlet electrical box home depot

Introducing the Inventor How To Offset Flange, a revolutionary solution designed to simplify and enhance your flange installation process. This innovative pr.

This video was create by BYU-Idaho for the ME 280 Mechanical Design course and demonstrates how an edge flange in the SolidWorks Sheet Metal module can be ed.

Normally Small Joggles formed in sheet metal work from 0.7mm to 3mm thick and up to a width of 140mm. How to joggle sheet metal with custom offset dies? Step 1: To define joggle in sheet metal after completing joggle tools to ensure quality, the sheet metal joggle tool will be tested to make a joggle in sheet metal on the joggle bender machine.

Here we show you how to adjust a round sheet metal duct elbow for 90°, 45°, 35° or from 0° to 90° or anything in between. It may seem confusing adjusting a r. Snip all four corners of the duct on both ends for a distance of 1 inch, and bend back the metal slightly to form flanges. 6. Connect the Offset. Slide the offset onto the straight run of duct that has already been installed, and push until the flange covers it. Drive sheet metal screws into the flange to hold the offset to the duct. If you've done any metal work you've surely seen the price of patch panels. Today's goal is show you how to make sheet metal patch panels easy for anybody wi.Michael Housh from Housh Home Energy Experts shares his expertise with HVAC School. In this video, he shows how to make a sheet metal duct transition in the .

Learn autodesk inventor 2023 basic tutorial for beginner how to working with sheet metal#inventor #sheetmetal #mufasucadMaking a sheet metal bracket involves a series of steps: selecting the appropriate metal, accurately measuring and marking your design, cutting the metal, bending it into the desired shape, and finally, finishing and installing it. . Custom .

Creo 7 introduced multibody modeling, so you have the option to use some of the tools in Creo 8 (full implementation for sheet metal is in Creo 11). Create your offset wall as a separate body and then save that body to a part. You can then convert this new part to sheet metal from solid.Making the Funnel Neck. Draw a wedge shape on the sheet metal, making it 4 inches wide at the top and 2 inches wide at the bottom, and 6 inches in length. Form into an elongated cone so that the opening at the thin end is about ½ inch in diameter. Sand the metal where it overlaps and sand the edges of the metal smooth. Clamp into a cone shape. In this quick tip, we will cover some best practices with sheet metal in Fusion 360. Rule 1, flat patterns, and flange options are just a few of the tips cov.

Video title: How to Roll a Cone – Midland FabricationIn this video students James & Luke talk us through how to roll a cone in a set of pinch plate rolls. Th. Learn how to roll sheet metal into a cone with a DIY Snubber Attachment.Make your own simple Snubber to make rolling a steel cone easy.00:00 Intro What's a S.A sheet metal transition is generally a piece of duct work that changes in cross section from one shape to another, typically from a rectangle to a circle. You can model a part like this in Solid Edge sheet metal and flatten it. . Make an offset plane to represent the length of the transition. Open a sketch on the offset plane. The second . Watch this video and more in the "Solid Edge Sheet Metal Tutorials" playlist:http://www.youtube.com/watch?v=vwGSpl130XY&list=PLWZ_kkGONSI9-fDzk8NxDe6XC641Zh_.

Let’s delve into how to use CAD for making sheet metal unfolding drawings, starting with the basic unfolding calculations. Sheet Metal Unfolding Calculation Guide – How To Unfold Sheet Metal Step By Step. 1. Unfold at right angles . the deduction for each blade is 3.4,90-3.4 * 2=83.2. We offset 83.2 from each edge line, as shown in the . I am normally a refrigeration piper but I sheet metal once in a while. I need to make a transition in the field out of rect duct and cannot remember how to lay it out. I am not talking about a four side transition. I remember that you draw an x on the offsetting side but cannot remember what to do next. I also remember that if you are growing too much that you .

Z bending. Definition: The bending process in which a material is bent in a zigzag pattern is referred to as Z bending. Standard bending process range: The height of the Z bend must be greater than the sum of the apothem of the V .

Not too long ago I, like many of you, sincerely thought that the way of making any kinds of sheet metal fittings is only possible by using sheet metal brake and metal forming machines! Not anymore: From late Fall and Winter of 2015 through May 2016 I made more than twenty most frequently-used sheet metal fittings without using any of these very .

how to offset sheet metal

Study with Quizlet and memorize flashcards containing terms like Who is born at the start of the film?, How does Amelie's mother die?, Amelie leaves home and gets a job as a __________ in the Montmartre café. and more.

how to make a sheet metal offset|how to offset material