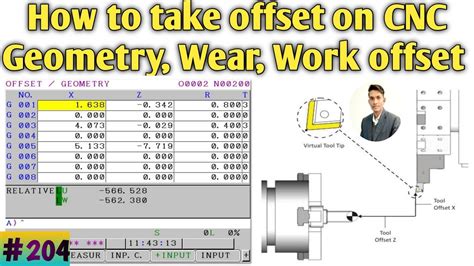

cnc machine offset setting By setting your tool length the correct way (my way), the stored offset is the actual tool length and you can do a rough check with your steel ruler before proving your program. Auto tool length measurement will always give . In sheet metal fabrication, the flange length (or flange height) is the distance between the bend and the part’s edge or the next feature, such as a hole or another bend. If a flange is too short, the sheet metal will slip into the v-shaped die during forming, preventing us from bending the material.

0 · what is wear offset

1 · what is tool length offset

2 · offset turning on cnc lathe

3 · offset meaning in cnc programming

4 · offset in cnc lathe

5 · geometry vs wear offsets

6 · cnc work offsets

7 · cnc tool offsets explained

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product. Large fab shops e.

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise .

cnc turning spare parts supplier

CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, . By setting your tool length the correct way (my way), the stored offset is the actual tool length and you can do a rough check with your steel ruler before proving your program. Auto tool length measurement will always give .This Tool Offsetting Routine is supported by most CNC machines. No need to face the top of your part to set your tools or work offset. Just calculate the distance between the top of the gauge and the top of your part. A dial indicator .

Once you set one of these all you need do is use the G code (54 to 59) and the machine will use that offset. Each one of these G Codes represents a datum position on the machine. G0 G54 X0 Y0 (Rapid to X0 Y0 using G54)

cnc turning machining aluminium parts factory

Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine.Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can . Begin by referencing your CNC machine’s manual or seeking online tutorials for guidance tailored to your specific machine model. Typically, the process involves homing the machine, setting the workpiece in place, and . Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.

cnc turning inserts types manufacturer

Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise measurement techniques, and implementing effective offset management strategies, operators can optimize their CNC machining processes.

In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, machinists can achieve precise machining, eliminate . By setting your tool length the correct way (my way), the stored offset is the actual tool length and you can do a rough check with your steel ruler before proving your program. Auto tool length measurement will always give actual tool length and so will a tool pre-setter.This Tool Offsetting Routine is supported by most CNC machines. No need to face the top of your part to set your tools or work offset. Just calculate the distance between the top of the gauge and the top of your part. A dial indicator can be used to set the Z Work Offset; A tool pre-setter can be used to set the tool offsets.

Once you set one of these all you need do is use the G code (54 to 59) and the machine will use that offset. Each one of these G Codes represents a datum position on the machine. G0 G54 X0 Y0 (Rapid to X0 Y0 using G54)

Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine.

Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can achieve precise results and maximize the efficiency of your turning operations. Begin by referencing your CNC machine’s manual or seeking online tutorials for guidance tailored to your specific machine model. Typically, the process involves homing the machine, setting the workpiece in place, and then defining the work offset coordinates.

what is wear offset

what is tool length offset

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.Mastering CNC machine offsets is a vital skill for achieving accurate and precise machining results consistently. By understanding the various types of offsets, following precise measurement techniques, and implementing effective offset management strategies, operators can optimize their CNC machining processes.

In this post I am going to explain what cnc offsets are, how they are used, and how they relate to a machine reference point or home position. But first I should begin by explaining the basic rules that cnc machines operate by.

offset turning on cnc lathe

CNC machine offsets are compensation values applied to tool positioning to account for variations in tool dimensions, machine alignment, and part geometry. By correctly setting the offsets, machinists can achieve precise machining, eliminate . By setting your tool length the correct way (my way), the stored offset is the actual tool length and you can do a rough check with your steel ruler before proving your program. Auto tool length measurement will always give actual tool length and so will a tool pre-setter.This Tool Offsetting Routine is supported by most CNC machines. No need to face the top of your part to set your tools or work offset. Just calculate the distance between the top of the gauge and the top of your part. A dial indicator can be used to set the Z Work Offset; A tool pre-setter can be used to set the tool offsets.

Once you set one of these all you need do is use the G code (54 to 59) and the machine will use that offset. Each one of these G Codes represents a datum position on the machine. G0 G54 X0 Y0 (Rapid to X0 Y0 using G54)

Master CNC programming with our guide on G10 codes. Learn to set work offsets like G54 and G55, automate setups, and enhance efficiency on your CNC machine.Mastering offset turning on a CNC lathe is a valuable skill that can greatly enhance your machining capabilities. By understanding how to properly set up and utilize offsets, you can achieve precise results and maximize the efficiency of your turning operations.

cnc tornos

cnc turning services berkshire

There are currently three materials used for poles: wood, steel and fibreglass. Wooden poles vary in length from 7 to 15m depending on the span the lines need to cover. Owner of the pole – In this case BT. Older poles may also be marked as GPO or PO. The punch hole sign is a testing cycle sign. This label is for internal Openreach use.

cnc machine offset setting|cnc work offsets