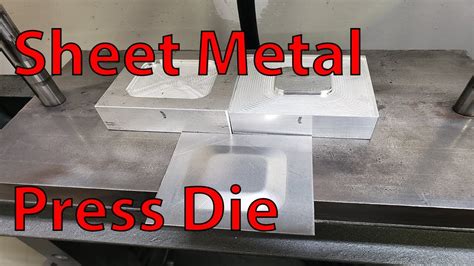

press forming sheet metal parts A metal forming press, also known as a stamping press, is a machine tool used to precisely shape and cut metal typically using upward and downward movements. . Hydroforming is a cost-effective metal fabricating process that can form . Once the connections are made and secured, the junction box is closed with a cover or lid. This cover provides an additional layer of protection, preventing dust, moisture, and accidental contact with the wires inside. It also helps contain any potential sparks or heat generated by the connections. 7. Access for Maintenance and Inspection

0 · sheet metal forming press dies

1 · sheet metal fabrication handbook pdf

2 · sheet metal die design pdf

3 · sheet metal calculations pdf

4 · press forming process step by

5 · forming stainless steel sheet metal

6 · forming sheet metal by hand

7 · forming aluminum sheet by hand

The answer is that the Red Wire is the Hot Wire from the switch itself. You are wiring your fixture into a junction box where buku wires come together. Hook the white to white, ground to ground and RED to the BLACK Light Fixture Wires.

The process is used to (as the name suggests) make bends and curves on the metal sheet in a straight line. With press brakes, the metal is put or clamped into place and then bent to the required angle. This sheet metal . Prototype parts or custom orders requiring fast turnaround times benefit from using sheet metal forming over slower techniques like casting or machining from billet. Most sheet metal parts can be formed with the single .

6.2.1. Metal Forming, Stamping, and Forging. One of the most significant uses of hydraulic presses is in metal forming, where the press shapes and molds metal into complex parts. Stamping and forging are specific .

A metal forming press, also known as a stamping press, is a machine tool used to precisely shape and cut metal typically using upward and downward movements. . Hydroforming is a cost-effective metal fabricating process that can form .The FluidForming sheet metal forming process accommodates integrated logos, undercuts, organic forms, deep drawn parts, and even components with curves that would be likely to wrinkle or tear with traditional metal forming methods. . Press brake forming is a fundamental process in metalworking that involves the bending and shaping of sheet metal. The press brake forming process is a highly flexible and versatile metal fabrication method that can produce various metal parts shapes. Here are the key process steps involved in press brake forming:

Sheet metal fabrication for chassis, tanks, enclosures, and other sheet metal parts. Last updated on February 23rd, 2024 at 08:51 am . Using a regular press brake to accomplish a complex bend often results in one of the metal legs twisting out of control—or crashing into the die itself. . The best method for forming deep boxes or U shapes .

Note: Fabricating sheet metal parts for the aviation industry is similar to standard procedures. The only difference is using specialized techniques to guarantee accuracy and part consistency. Still, it entails: Cutting sheet metal; Forming sheet metal; Joining sheet metal technique or assembly operations – welding, riveting, etc. Finishing .

Sheet metal stretch forming is a metal shaping process that involves stretching sheet metal over a form die. Stretch forming is key in aerospace sheet metal fabrication for creating strong, lightweight aircraft parts in complex shapes. With the bulldozer attachments on our Cyril Bath 800 ton stretch press, we can stretch form reverse forms. By . Some metal forming companies dub the blanking process OP05, and others OP10. For example, when processing parts that include an offline blank die, OP10 typically refers to the blanking operation. In other cases, metal formers label the first forming operation OP10 and use OP05 to refer to blanking.

6.2.1. Metal Forming, Stamping, and Forging. One of the most significant uses of hydraulic presses is in metal forming, where the press shapes and molds metal into complex parts. Stamping and forging are specific methods within this category: Stamping: Involves pressing sheet metal into a die to create precise shapes or patterns. Hydraulic . Hi all, Does the Fusion 360 sheet metal workspace have tools for created impressed/formed sheet metal parts? For example, if I wanted to press in some text on a sheet metal part. I can do a simple extrude and filet but this does not cause the metal to come out on the other side. How do I create so that if I send the file to a manufacturer they will know to only . Sheet metal forming is the transformation of a metal sheet into a fully realized 3D product. Check out our guide to the sheet metal forming process. . Techniques like bending and stamping employ simple dies and presses to deform sheet metal into shapes. . Most sheet metal parts can be formed with the single stroke of a press or strike by a . Compared to conventional sheet metal forming processes, advantages of RPF processes are low cost (tooling), dimensional accuracy, high flexibility, and short lead-time for tooling and part, as .

sheet metal forming press dies

Metal Forming is further classified into Massive Forming and Sheet Metal Forming. . 3 thoughts on “Mechanical Power Press: Uses, Working, Types, Parts, Drive System & Safety” Guangduan. August 25, 2022 at 7:14 am. Really, This Blog is very Helpful and informative. This blog are every line impressed me.

sheet metal fabrication handbook pdf

Sheet Hydroforming is a method to form metal, plastic, and composite parts using a diaphragm pressurized with fluid and a single, un-mated tool. When the cycle is . and traditional forming, early sheet hydroforming presses revolutionized low-volume, high-mix production facilities. However, the secret to making quality parts rested with .We Technomech are Designer, Developer, Manufacturer, Supplier of Sheet Metal Pressed Components, Pressed Component, Sheet Metal Forming, Sheet Metal Press Parts . Using 3D printed forms to bend sheet metal isn’t exactly new. We’ve seen several people create custom dies for their brakes, and the results have shown the concept has merit for small-s.Rubber pad forming process, 1: bottom of the press. 2: lower die. 3: sheet metal. 4: rubber pad. 5: top of the press. Rubber pad forming (RPF) is a metalworking process where sheet metal is pressed between a die and a rubber block, made of polyurethane.Under pressure, the rubber and sheet metal are driven into the die and conform to its shape, forming the part.

An Introduction Stretch forming is a metal forming process that simultaneously stretches and bends a selected material over a machined form, called a die, to form a part with one or several different curve radii. This process produces perfectly curved parts with smooth, wrinkle-free contours. The aerospace industry initially invented the stretch forming presses [.]

Sheet Metal Parts Deburring And Hand Finishing; Hydro form – rubber head Press Forming; Brake Press Forming; Punch Press Blank And Pierce Stamping; Hand Form And Aligning Sheet Metal Parts; AOG delivery capability "The next time you have a requirement for formed sheet metal parts why not give me a call at (620) 326-7481."From metal cans to protective housing for hardware, parts created by sheet metal forming are found everywhere in our daily lives. In this article, learn the basics of sheet metals, the various sheet metal forming processes, and how to reduce the cost of sheet metal forming with rapid tooling and 3D printed dies.

We specialize in sheet metal forming and bending services for medical, aerospace, national defense, telecommunications, and process control instrumentation applications for clients worldwide. Press Brake Metal Forming. Precision press brake forming is used to form and bend sheet metal into V-shaped, U-shaped, and channel-shaped parts.

Last updated on May 2nd, 2024 at 11:57 am. Approved Sheet Metal has the expertise and capabilities to make almost any precision sheet metal part our customers request. Sometimes we just have to think outside the box to devise a creative solution. When it comes to sheet metal forming U-shaped parts, for instance, the maximum depth our press brake can .Applications for Press Brake Formed Parts Press brake forming is a commonly used manufacturing process in industries such as energy storage, computer electronics, robotics, medical, and aerospace. Common sheet metal parts fabricated with forming include: brackets busbars covers panels mounts housings or enclosuresMacrodyne Stretch Forming Presses are available in a variety of configurations to form Sheet Metal, Extrusions, and Brake-Formed Profile Parts by using the Stretch Forming method. The Sheet Press is typically used to form large sheets, while the Swing Arm (V-Press) is used for Extrusions and Break Formed parts.

- space between the punch and the die Major factor in determining the shape and quality of the sheared edge As clearance increases the deformation zone becomes large and the sheared edge surface becomes rougher because the formability of the sheared part can be influence by the quality of its sheared edges, clearance control is important Dependent on: type of material and . A very detailed review of these technologies was reported by Psyk et al. (2011) and Mynors and Zhang (2002) illustrating their advantages compared to quasistatic one-sided forming processes described by Singh (2003): the short duration of the applied forming pressure did not necessitate the large press sizes required for quasistatic forming .

ruler size pencil box metal

The process of sheet metal forming includes bending, wherein the application of force on a sheet metal workpiece results in a bend at a specific angle to create the desired shape. . Unlimited possibilities and configurations allow us to cost-effectively produce the most demanding parts with our CNC Press Brakes. Metal Bending and Forming at .

rs232 cable for cnc machines

sheet metal die design pdf

Identifying and legend fuse box Honda Civic 1991-1995.

press forming sheet metal parts|forming aluminum sheet by hand