electrical pull box dimensions Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on . Sheet metal thickness is denoted by gauge, sometimes spelled gage, which indicates a standard thickness before processing. Click here for a Gauge to mm Conversion Chart. Processing may include polishing, or the applying of protective plastics which will decrease or increase a sheet’s thickness respectively.

0 · standard electrical pull box sizes

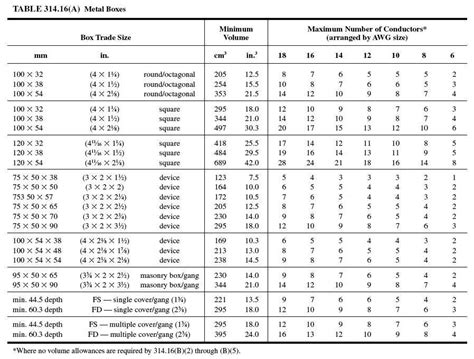

1 · pull box standard sizes

2 · nec box size chart

3 · junction box sizes chart

4 · electrical pull box calculator

5 · electrical box size chart

6 · electrical box size calculator

7 · distance between underground pull boxes

A good metal drill bit will have a thick core, a split and chiseled web, a low deep rake angle behind the cutting edge, and a good relief angle behind that. Both cutting edges should be equal length and close to 135°.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact us or call 800-767-1576 if you need .Using improper equipment to house your underground electrical systems can lead . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and . Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on .

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example. Pull boxes, junction boxes, and conduit bodies must be sized to allow conductors 4 AWG and larger to be installed without damage to the conductor insulation. The NEC provides sizing requirements in Sec. 314.28.

Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances .The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in .Effortlessly calculate the required electrical pull box size for your wiring project using our Electrical Pull Box Size Calculator. Input the number of conductors and select the box type to get .

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls. Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

Pull boxes, junction boxes, and conduit bodies must be sized to allow conductors 4 AWG and larger to be installed without damage to the conductor insulation. The NEC provides sizing requirements in Sec. 314.28. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.

standard electrical pull box sizes

Effortlessly calculate the required electrical pull box size for your wiring project using our Electrical Pull Box Size Calculator. Input the number of conductors and select the box type to get accurate results.

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. Use 314.28(A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example. Pull boxes, junction boxes, and conduit bodies must be sized to allow conductors 4 AWG and larger to be installed without damage to the conductor insulation. The NEC provides sizing requirements in Sec. 314.28. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.

pull box standard sizes

$25.65

electrical pull box dimensions|junction box sizes chart