cnc control system manufacturers A CNC retrofit upgrades the control system, the servo and spindle motors, the motor . Full Job Description We are currently seeking an experienced Fitter-Welder. The position requires the ability to fabricate and weld a wide range of materials such as Steel, Stainless and other .

0 · what is FANUC in cnc

1 · types of cnc control systems

2 · pc based cnc control system

3 · numerically controlled machine tools

4 · how cnc machine is controlled

5 · cnc machine tool control systems

6 · cnc machine control systems

7 · best diy cnc controller board

Learn how to properly adjust an off-centered bathroom vanity light and maintain symmetry and balance in your bathroom design. Follow these step-by-step instructions to ensure your vanity light is installed correctly and .

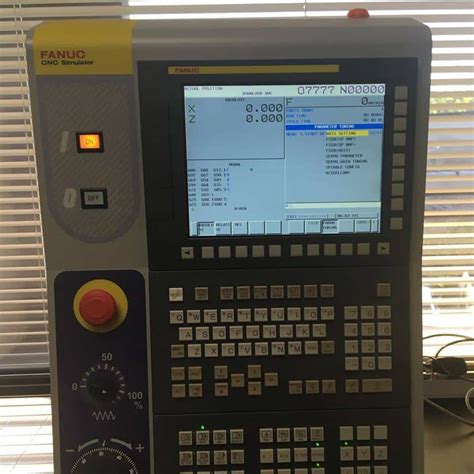

FANUC develops cutting edge CNC and motion control systems for a wide range of applications - From basic high-volume, high-repetition commodity production, to unique, highly complex parts that require the highest precision and advanced machining techniques.Panel iH Pro Industrial PC. FANUC PANEL iH Pro is an industrial panel PC that can .Explore FANUC's CNC software solutions to help improve CNC machine .FANUC 5 axis CNC machining solutions are the most reliable 5th axis CNCs in the .

A CNC retrofit upgrades the control system, the servo and spindle motors, the motor .

FANUC has precision motion control products to assist in a variety of .FANUC CNC Systems and Solutions. FANUC CNCs are known for their rock .

FANUC is the world's leading supplier of automation for manufacturing including robotics, CNCs and Motion Control, and ROBOMACHINE machining centers.FANUC develops cutting edge CNC and motion control systems for a wide range of applications - From basic high-volume, high-repetition commodity production, to unique, highly complex parts that require the highest precision and advanced machining techniques.

what is FANUC in cnc

FANUC is the world's leading supplier of automation for manufacturing including robotics, CNCs and Motion Control, and ROBOMACHINE machining centers. Discover the top 10 CNC systems that are revolutionizing industries, as we explore their features, benefits, and the cutting-edge technologies that set them apart. Get ready to uncover the secrets behind the machines that are driving innovation and efficiency in manufacturing today. 1. Japan FUNAC CNC system.FANUC CNC Systems and Solutions. FANUC CNCs are known for their rock-solid reliability and unbeatable performance. We have controls to meet all machining needs, from highly complex 5-axis applications to running precision ancillary equipment. All with .

Okuma America Corporation helps users gain competitive advantage through the open possibilities of our CNC machine tools and advanced technologies.

Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines, various automation systems, and production support software and CNC equipment that support skill leveling and setup.

HEIDENHAIN offers a full range of CNC controls for all common types of milling and turning machines. From simple three-axis CNC machines to highly complex machining centers with up to 23 axes, HEIDENHAIN controls are always the right choice.For nearly 50 years Acu-Rite Solutions has represented the finest-quality readout systems, precision glass scales and CNC controls.Built-in with Delta's DMCNET motion bus, the CNC controllers can fulfill highly precise, high-speed, and smooth processing with the AC Servo System ASDA-A3 Series or ASDA-B3 Series, permanent magnet (PM) motors / induction motors (IM) for the spindle, and encoders.CS-Lab designs CNC motion control systems. We equip machine manufacturers, builders, modernizers, and hobbyists with well-known and valued in the CNC market motion controllers – CSMIO/IP, professional control software – simCNC, and servo drive systems.

FANUC develops cutting edge CNC and motion control systems for a wide range of applications - From basic high-volume, high-repetition commodity production, to unique, highly complex parts that require the highest precision and advanced machining techniques. FANUC is the world's leading supplier of automation for manufacturing including robotics, CNCs and Motion Control, and ROBOMACHINE machining centers. Discover the top 10 CNC systems that are revolutionizing industries, as we explore their features, benefits, and the cutting-edge technologies that set them apart. Get ready to uncover the secrets behind the machines that are driving innovation and efficiency in manufacturing today. 1. Japan FUNAC CNC system.FANUC CNC Systems and Solutions. FANUC CNCs are known for their rock-solid reliability and unbeatable performance. We have controls to meet all machining needs, from highly complex 5-axis applications to running precision ancillary equipment. All with .

Okuma America Corporation helps users gain competitive advantage through the open possibilities of our CNC machine tools and advanced technologies.Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines, various automation systems, and production support software and CNC equipment that support skill leveling and setup.HEIDENHAIN offers a full range of CNC controls for all common types of milling and turning machines. From simple three-axis CNC machines to highly complex machining centers with up to 23 axes, HEIDENHAIN controls are always the right choice.For nearly 50 years Acu-Rite Solutions has represented the finest-quality readout systems, precision glass scales and CNC controls.

Built-in with Delta's DMCNET motion bus, the CNC controllers can fulfill highly precise, high-speed, and smooth processing with the AC Servo System ASDA-A3 Series or ASDA-B3 Series, permanent magnet (PM) motors / induction motors (IM) for the spindle, and encoders.

marine cnc machines

manutenção torno cnc

The vertical turning centers are used for heavy components, horizontal types are used widely for the general applications, so let’s explain 8 parts of a CNC lathe! 1. Headstock. The first part of CNC lathe is headstock which is located in the left side of the machine.

cnc control system manufacturers|types of cnc control systems