general dimensional tolerances for sheet metal formed parts Sheet metal tolerances are the maximum permissible dimension deviation range during sheet metal processing. This concept is vital because it directly affects the quality and performance of the product. Ensuring that every product falls .

Carry your favorite soup or even oatmeal in this modern stainless steel food jar from Thermos. It has double-wall vacuum insulation to keep meals hot or cold and comes with an ergonomically designed foldable spoon for .

0 · sheet metal tolerances pdf

1 · sheet metal tolerance table

2 · sheet metal specifications

3 · sheet metal diameter chart pdf

4 · flat stamping tolerance table

5 · flat stamping tolerance chart

6 · edge bulging tolerance sheet metal

7 · critical dimensions of sheet metal

They provide faster installations, precise alignment adjustments, and safety features that simplify the process of installing cabinets. Shop and Save on Our Wide Selection of Cabinet Hanging Systems. Discover Great Prices, Special Offers & Best Customer Service.

sheet metal tolerances pdf

Understanding sheet metal tolerances is crucial for ensuring that parts fit together perfectly in any mechanical project. This article will explore the different types of tolerances used in flat and formed stamping parts, from . Sheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of .

We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These .

how to fix a bent metal box spring

Because parts are formed from a single sheet of metal, designs must maintain a uniform thickness. Factors like bend radius and feature-to-feature cut distances should be considered. . ISO 2768 is an important standard for general tolerances in sheet metal fabrication. It specifies tolerance classes for linear dimensions, angular dimensions (ISO 2768 .Sheet metal tolerances are the maximum permissible dimension deviation range during sheet metal processing. This concept is vital because it directly affects the quality and performance of the product. Ensuring that every product falls . Even though the term is used all the time, the reality of manufacturing tolerances can get quite complicated depending on the process in question. This post will compare machining, 3D printing, and sheet metal .

Let’s explore the three primary metal tolerancing categories in sheet metal fabrication: #1. Essential Tolerances. Essential tolerances are those necessary for fundamental fit and function. Design requirements and industry .1. General dimension tolerance for parts formed by press working from sheet metal JIS B 0408 -1991 Table 1. General dimension tolerances of punching Units: mm Standard dimension Grade Grade A Grade B Grade C More than 1000 No more than 2000 More than 400 No more than 1000 More than 120 No more than 400 More than 30 No more than 120 More than .

General Dimensional Tolerances for Parts Formed by Press Working from Sheet Metal active, Most Current Buy Now . Document History. JIS B 0408 February 1, 1991 General Dimensional Tolerances for Parts Formed by Press Working from Sheet Metal A description is not available for this item. JIS B 0408. February 1, 1991 . Common Standards for Dimensional tolerances. We adhere to various standards in sheet metal fabrication. ISO 2768 is the most widely used standard for general tolerances, while ANSI Y14.5 is more specific. These standards serve as a guide to ensure consistency in production regardless of the project’s complexity.. It’s not just about compliance; it’s about .

GENERAL DIMENSIONAL TOLERANCES FOR PARTS FORMED Excerpt from JIS B 0408 /0410(1991) . General dimensional tolerance of blanking Unit:mm 1. General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. Over 120 to 400 incl. Over 30 to 120 incl.This Japanese Industrial Standard specifies general dimensional tolerances for parts formed by press working from sheet metal. Furthermore, the parts formed by press working from sheet metal mean those which have been formed by press working of punching, bending and drawing from sheet metal, and do not include those formed by shear working from sheet metal. Common Tolerancing Problems in Metal Fabrication. We frequently receive RFQs for parts with tolerances that exceed what is achievable in standard fabrication. Most of these issues are related to sheet metal forming, such as achieving ±0.005 tolerance across multiple bends, which surpasses our recommended default sheet metal tolerances.Additionally, we . This Japanese Industrial Standard specifies general dimensional tolerances for parts formed by press working from sheet metal. Furthermore, the parts formed by press working from sheet metal mean those which have been formed by press working of punching, bending and drawing from sheet metal, and do not include those formed by shear working from sheet metal.

APPENDIX 2 GENERAL DIMENSIONAL TOLERANCES FOR PARTS FORMED BY PRESS WORKING FROM SHEET METAL 1. Scope This standard covers the system of dimensional tolerances for parts press-formed from sheet metals specified in already issued drawings which were subjected to the application of TTDS 5-3. Remarks: 1.GENERAL DIMENSIONAL TOLERANCES FOR PARTS FORMED Excerpt from JIS B 0408 /0410(1991) . General dimensional tolerance of blanking Unit:mm 1. General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. Over 120 to 400 incl. Over 30 to 120 incl.

jis04081991-General dimensional tolerances for parts formed by press working from sheet metal- HOME; PRODUCTS. Publisher Collections; Standards Connect; Standards Packages; Selected Standards; Best Selling Standards and Packages; INDUSTRY COLLECTIONS; 100 Newest Standards and Packages;

Uncover the basics of sheet metal tolerances, including measurement methods and industry standards for perfect parts. . General tolerances for linear and angular dimensions. JIS B 0419: General tolerances for form and position. 6. Practical Application of Standards . Sheet metal fabrication is the process of forming parts from a metal sheet .

This Japanese Industrial Standard specifies general dimensional tolerances for parts formed by press working from sheet metal. Furthermore, the parts formed by press working from sheet metal mean those which have been formed by press working of punching, bending and drawing from sheet metal, and do not include those formed by shear working from sheet metal.GENERAL DIMENSIONAL TOLERANCES FOR PARTS FORMED Excerpt from JIS B 0408 /0410(1991) . General dimensional tolerance of blanking Unit:mm 1. General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. Over 120 to 400 incl. Over 30 to 120 incl.General tolerance ISO 2768 does not specify where to use these tolerances. You should define tolerance class as per design requirements and manufacturing capability. For example, the manufacturer recommends ISO 2768-mk for sheet metal parts .1. General dimension tolerance for parts formed by press working from sheet metal JIS B 0408 -1991 Table 1. General dimension tolerances of punching Units: mm Standard dimension Grade Grade A Grade B Grade C More than 1000 No more than 2000 More than 400 No more than 1000 More than 120 No more than 400 More than 30 No more than 120 More than .

GENERAL DIMENSIONAL TOLERANCES FOR PARTS FORMED Excerpt from JIS B 0408 /0410(1991) . General dimensional tolerance of blanking Unit:mm 1. General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. Over 120 to 400 incl. Over 30 to 120 incl.General Dimensional Tolerances for Parts Formed by Sheet-Metal Stamping JIS B 0408-1991- Table 1 General Tolerances for Pressed Parts (Unit: mm) Standard Dimension Category Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.1. General dimension tolerance for parts formed by press working from sheet metal JIS B 0408 -1991 Table 1. General dimension tolerances of punching Units: mm Standard dimension Grade Grade A Grade B Grade C More than 1000 No more than 2000 More than 400 No more than 1000 More than 120 No more than 400 More than 30 No more than 120 More than .

JIS B 0408:1991 General dimensional tolerances for parts formed by press working from sheet metal. Standards Manage Your Business. We Manage Your Standards. Shop All . JIS B 0408:1991. General dimensional tolerances for parts formed by press working from sheet metal. General Information. Status : ACTIVE. Standard Type: Main. Document No: JIS .It applies to the dimensions of parts that are produced by metal removal or parts that are formed from sheet metal. NOTES 2 These tolerances may be suitable for use with materials other than metal. 3 Parallel International Standards exist or are planned, e.g. see IS0 60621) for castings.

Tolerances are the acceptable range of variations in the dimensions of sheet metal parts that we manufacture. Tolerances are a guarantee that our parts will fit and perform as intended for your projects, just as they did for Jack Garcia and his crew. There are three types of sheet metal tolerances: Material, Dimensional, and Geometric.・ Tolerances for Dimensions and Angular Dimensions Without Individual Tolerance Indications (Excerpt From JIS B 0405:1991) ・ General Dimensional Tolerances for Parts Formed by Sheet-Metal Stamping (Excerpt From JIS B 0408:1991)

General dimensional tolerances for parts form ed by press worki ng from sh eet metal 1. Scope This standard covers general dimensional tolerances, in three tolerance classes, applicable to punching, bending, deep drawing and hole diameter dimensions of .The document discusses technical standards for dimensional tolerances in manufacturing parts from pressing, bending, punching and shearing sheet metal based on Japanese Industrial Standards. It provides tables with tolerance grades and allowed dimensional variations for different standard part sizes. Tolerance grades include precision, medium and coarse classes. .

This Japanese Industrial Standard specifies general dimensional tolerances for parts formed by press working from sheet metal. Furthermore, the parts formed by press working from sheet metal mean those which have been formed by press working of punching, bending and drawing from sheet metal, and do not include those formed by shear working from sheet metal.

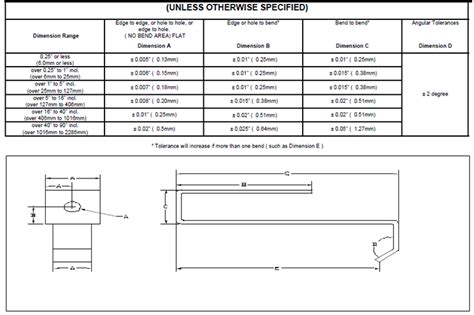

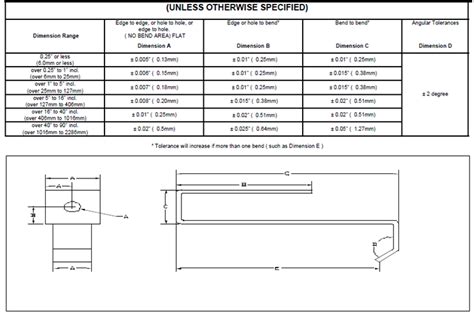

General Dimensional Tolerances for Sheet Metal Formed Parts (Unless Otherwise Specified) Dimensional Range Edge to edge or hole to hole, or edge to edge (No bend area) Flat Edge or Hole to Bend Bend to bend Angular Tolerances 0.25" or less (6mm or less) ±0.005"(0.13mm) ±0.01"(0.25m m) ±0.01"(0.25mm) ±1 degree Over 0.25" to 1" (over 6mm to .Citation preview. TOYOTA ENGINEERING STANDARD NO.: TITLE: CLASS: TSZ2202G General dimensional tolerances for parts formed by press working from sheet metal C2 Established/Revised: Rev. 5 ( Nov. 2011 ) This standard was subjected to a periodic review and has been partly revised, although there are no significant changes. Prepared and Written by: .

how to drill octagon junction box

Wall Mount Locking Drop Box, Heavy Duty Steel Mailbox for Rent Payments, Mail, Keys, Cash, Checks - Safe Storage Dropbox for After Hours Deposits W500 (Black)

general dimensional tolerances for sheet metal formed parts|sheet metal tolerances pdf