2.5 axis cnc machining For hobbyists and starting professionals, 2D, 2.5D, and 3D contouring are the most popular processes by far, with each one offering their . 1 CA series ordinary horizontal lathe is used to turning internal and external cylindrical surface, conical surface, and other rotating surface, turning various metric and inch, modulus and pitch thread, and the pitch diameter of the thread and pull the drilling and oil tank etc., is general very strong horizontal lathe, Widely applicable batch .In this blog post, we'll take a look at some of the top wholesale CNC horizontal lathe machine manufacturers you should be aware of to help you make the right choice when purchasing .

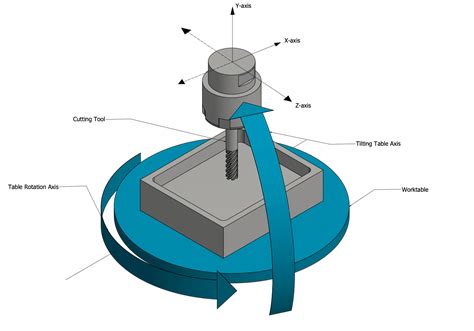

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

Sheet metal manufacturing can be customized to create a wide range of parts, including brackets, covers, frames, enclosures, and housings. Sheet metal fabrication process can create complex and intricate shapes with accuracy and precision.

A 2.5D machine, also called a two-and-a-half-axis mill, possesses the capability to translate in all three axes but can perform the cutting operation only in two of the three axes at a time due to hardware or software limitations, or a machine that has a solenoid instead of a true, linear Z axis. A typical example . See moreIn machining, 2.5D refers to a surface which is a projection of a plane into 3rd dimension – although the object is 3-dimensional, there are no overhanging elements possible. Objects of this type are often represented . See more

2.5D objects are often greatly preferred for machining, as it is easy to generate G-code for them in an efficient, often close to optimal fashion, while optimal cutting tool paths for true 3 . See more

In this video we find out about what 2.5 Axis machining is and how it can help your manufacturing process. Solid Solutions is the leading SOLIDWORKS services. For hobbyists and starting professionals, 2D, 2.5D, and 3D contouring are the most popular processes by far, with each one offering their .One such innovative tool is the 2.5 axis CNC machine - a powerful and versatile solution that combines the benefits of 2-axis and 3-axis machines. In this blog post, we will explore the .

A 2.5D machine, also called a two-and-a-half-axis mill, possesses the capability to translate in all three axes but can perform the cutting operation only in two of the three axes at a time due to hardware or software limitations, or a machine that has a solenoid instead of a true, linear Z axis. A typical example involves an XY table that .

In this video we find out about what 2.5 Axis machining is and how it can help your manufacturing process. Solid Solutions is the leading SOLIDWORKS services.

For hobbyists and starting professionals, 2D, 2.5D, and 3D contouring are the most popular processes by far, with each one offering their own opportunities. Let’s dive in to learn about the main differences. 2D Contouring using the Profile Toolpath in Vectric software.One such innovative tool is the 2.5 axis CNC machine - a powerful and versatile solution that combines the benefits of 2-axis and 3-axis machines. In this blog post, we will explore the capabilities, applications, and advantages of 2.5 axis CNC machines.

Read a blueprint and understand the necessary steps to machine a brake assembly. Create basic CAD models and program 2.5 axis toolpaths. Set up a Haas vertical mill. Run and validate an NC program and inspect machined parts. Create a new setup to machine the brake caliper, simulate all toolpaths, and machine a real brake caliper.An axis is a direction of motion controlled by the CNC machine control. It can be linear (motion along a straight line) or circular (a rotary motion). The number of axes a machine has determines it's machining capabilities. A 2.5 axis machine really has three moving axes, but only two axes can move together (most machines sold today are full . Three-axis machining is a natural progression from 2.5-axis machining with the incorporation of a true Z-axis. 3-axis machining is still commonly used across the manufacturing industry today. CAD and CAM software are essential for any computer numerical control (CNC) machine — the more axes involved, the more complicated it is to program . Because you can only cut on one face in the Z axis, this is called 2.5D CNC. This is a big deal when you’re thinking about design software. Most people think that they need a full-featured 3D design program in order to design parts for their CNC milling machine.

what is 5 axis milling

2.5 Axis or 2.5D CNC 2.5D is a term used to describe a manufacturing process where there are no parts of the workpiece that overhang. In essence, all sections needing machining are accessible by a straightforward downward motion from the top.

what does 5 axis mean

2 1/2 axis work is that which may be done with 2 axis interpolation, the third axis departures not being interpolated. Note that most controls allow the programmer to choose the 2 axes to be interpolated by calling the plane of interpolation with G17, G18, or G19.A 2.5D machine, also called a two-and-a-half-axis mill, possesses the capability to translate in all three axes but can perform the cutting operation only in two of the three axes at a time due to hardware or software limitations, or a machine that has a solenoid instead of a true, linear Z axis. A typical example involves an XY table that .In this video we find out about what 2.5 Axis machining is and how it can help your manufacturing process. Solid Solutions is the leading SOLIDWORKS services. For hobbyists and starting professionals, 2D, 2.5D, and 3D contouring are the most popular processes by far, with each one offering their own opportunities. Let’s dive in to learn about the main differences. 2D Contouring using the Profile Toolpath in Vectric software.

One such innovative tool is the 2.5 axis CNC machine - a powerful and versatile solution that combines the benefits of 2-axis and 3-axis machines. In this blog post, we will explore the capabilities, applications, and advantages of 2.5 axis CNC machines.

Read a blueprint and understand the necessary steps to machine a brake assembly. Create basic CAD models and program 2.5 axis toolpaths. Set up a Haas vertical mill. Run and validate an NC program and inspect machined parts. Create a new setup to machine the brake caliper, simulate all toolpaths, and machine a real brake caliper.An axis is a direction of motion controlled by the CNC machine control. It can be linear (motion along a straight line) or circular (a rotary motion). The number of axes a machine has determines it's machining capabilities. A 2.5 axis machine really has three moving axes, but only two axes can move together (most machines sold today are full .

Three-axis machining is a natural progression from 2.5-axis machining with the incorporation of a true Z-axis. 3-axis machining is still commonly used across the manufacturing industry today. CAD and CAM software are essential for any computer numerical control (CNC) machine — the more axes involved, the more complicated it is to program .

Because you can only cut on one face in the Z axis, this is called 2.5D CNC. This is a big deal when you’re thinking about design software. Most people think that they need a full-featured 3D design program in order to design parts for their CNC milling machine. 2.5 Axis or 2.5D CNC 2.5D is a term used to describe a manufacturing process where there are no parts of the workpiece that overhang. In essence, all sections needing machining are accessible by a straightforward downward motion from the top.

high quality custom metal parts supplier

high quality junction box cover supplier

small 5 axis cnc mill

Cabinet Hinges; Cabinet Knobs Pulls & Handles. Amerock; Belwith Hickory Hardware; Berenson Hardware; Stainless Steel Bar Pulls; Specialty Pulls; Gyford Stand-Offs; Abrasives & Woodworking. Sanding Accessories; 3M Sanding .

2.5 axis cnc machining|5 axis trunnion machining