sheet metal holder for milling small parts Includes: Parle Tool Holder, Cat C40-M25EM4; Erickson Shell Mill Holder, Cat No. BT40BSM2C100177; Maritool Tool Holder, Cat No. 40 ER32-3.0; Tag: 319455 Auction Details Machine Shop & Inspection Equipment, Cabinets, Tools, Material Handling and More

The little hook at the end of your measuring tape is supposed to be a bit wiggly. Here’s why. The measuring tape’s metal end is designed to be slightly loose, as the movement allows for.

0 · Workholding Tip for Milling Small, Thin Metal Parts

1 · Tips/Techniques better suggestion for holding thin sheet metal for

2 · Seven Successful Workholding Methods

3 · General

4 · Fixtures for thin sheet milling?

5 · 8 Ways to Hold Material in Place While Machining with a CNC

Orbit Industries' Gangable Switch Boxes are used in the installation of switches, receptacles, and other electrical devices with 1-1/2", 2”, 2-1/4", 2-1/2", 2-3/4”, 3-1/2 depths. Selected models include 1/2”, 3/4" knockouts and non-metallic cable clamps, metal clad cable clamps, and locking grips for ease of installation and old work.

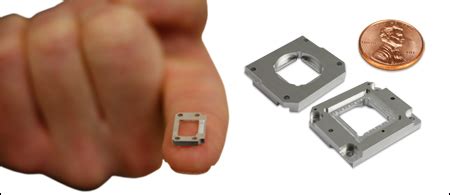

Perfect your milling process with Datron's expert tips for workholding small, thin metal parts, ensuring optimal results every time.I want to mill some pretty small sheet metal parts ( 1.25" long , up to 3/8" wide and from 0.032" sheet stainless (unknown pedigree). I tried the painters tape with super glue between them, .

Instead of carpet tape I lightly, and lightly is important, spray a thin coat of glue (I like 3M 90 or 77) on only one of the surfaces, usually the metal. It provides a uniform, thin . Then, I'd clamp the sheet metal to the angle iron with a piece of quality (dimensionally stable) plywood in between the sheet and angle iron. This way, you can mill .Holding your workpiece securely is essential to a successful project. In this post, I’ll discuss seven proven methods to hold your workpiece so you can cut it accurately. I’ll introduce each . Includes: Parle Tool Holder, Cat C40-M25EM4; Erickson Shell Mill Holder, Cat No. BT40BSM2C100177; Maritool Tool Holder, Cat No. 40 ER32-3.0; Tag: 319455 Auction Details Machine Shop & Inspection Equipment, Cabinets, Tools, Material Handling and More

Workholding Tip for Milling Small, Thin Metal Parts

End mill holders can be used with both solid and indexable end mills, making them a versatile tool holder option. 3. Shell Mill Holders\ Shell mill holders are similar to end mill holders, but they are designed to hold shell mills instead. Shell mills are larger cutting tools that are used for heavy-duty milling operations, such as roughing.Sheet Metal Components. We offer the sheet metal manufacturing solution, from single part or subassembly manufacture to turnkey solutions. Utilising the latest sheet metal manufacturing technology we offer metal bending, welding, spot . This item: Mill Arbor Holder, Threaded Taper Milling Holder Mill Arbor Taper Tool Holder for Milling Cutting(MT4-FMB22 M16) .49 $ 23 . 49 Get it Mar 7 - 20

pool light junction box home depot

True! I do work slow, but I'm not in any hurry. Working with small parts sometimes takes more time than working with big parts. Setting up the part for machining takes me the most time. I use a feeler gage to set the end mill to the work, do the math, set depth of cut, check speeds and enter into the DRO before machining. Amazon.com: VEVOR Mini Metal Lathe 8"x14", Mini Lathe Machine 2250 PRM Variable Speed Change,Precision Mini Lathe 600W Metal Working Lathe, Small Metal Lathe, Milling Machine for Various Types of Metal Turning : Tools & Home Improvement Machining small parts may seem daunting for a beginner, but it is pretty easy to get started. You also have the opportunity to make a comfortable living creating a busine . with enough power and speed to cut metal to full-on engraving. However, the mills are small and only make small parts, but they are great for beginners with a low budget .With such a small tool, your cutting forces reduce even further to prevent movement of the material. For very stubborn pieces, consider using a down-cutting end mill for finish cuts. Downcut tools push the material down while milling, instead of pulling up, which helps small pieces stay-put. 5) Mill Recessed Areas in Vacuum Table Sacrificial Layer

Tips/Techniques better suggestion for holding thin sheet metal for

With complete milling small parts production lines and experienced employees, can independently design, develop, manufacture, and test all products in an efficient manner. Throughout the whole process, our QC professionals will supervise each process to ensure product quality. From choosing suitable material to precision sheet metal fabrication, fabricating aerospace sheet metal parts can be challenging. The best part, today’s guide explores all fundamental facts about aerospace sheet metal fabrication. Whether you want to choose a suitable material, fabrication technique or understand practical applications – all information . How about using a vacuum table to hold the sheet metal and recirculate the coolant/cutting oil. Phil Pilgrim (PhiPi) Posts: 23,514 2011-08-14 22:06 edited 2011-08-14 22:06

Requirements for Milling Small Parts. When it comes to milling small parts, several requirements must be met to ensure the success of the operation. Here are the most critical ones: Precision: Because small parts have small features and tight tolerances, the milling process must be extremely precise to avoid errors or deviations from the design. The AdDoFeed series is designed to offer high feed milling capability for small parts machining. AddDoFeed uses size 02 inserts of 4 mm (5/32″) inscribed circles and offers close pitch cutter bodies with a small diameter indexable cutter.

This type of holder is commonly used for machining large workpieces such as steel structures, ships, and airplane parts. Arm Type Tool Holder: An arm-type tool holder is a crossbeam type of tool holder with a tool holder that moves along an arm structure. This type of holder is often used to achieve complex workpieces such as automobile engine .Self Tapping Sheet Metal Screws; Shoulder Screws; Slotted Hex Sheet Metal Screw; Seals & Ties. Cable Ties; . Small Machine; Storage & Workshop Equipment; Technical Reference & Software; Tool Holder; . Milling Chuck Holders. Features Balanced to G2.5 at 25,000 RPM.

As routers become more accurate and capable they are used increasingly to machine parts that, in the past, typically were machined on CNC milling machines. Routers with large machine tables and coupled with .

The tool holder segment includes various items for milling, drilling, turning and other machining processes. In most cases they allow the forces to be transferred between the tool and the machine. In addition to milling arbors and adapters, .

I don't know how many of these pieces you need to make, but if it were me, I'd clamp a piece of angle iron in a mill vise. Then, I'd clamp the sheet metal to the angle iron with a piece of quality (dimensionally stable) plywood in between the sheet and angle iron. This way, you can mill right through the plate into something soft.

Metal Turning Lathe, Metal Lathes, Tools & Parts. Busy Bee stocks a wide selection of metal turning lathes that will assist in all types of metal working, from hobbyists, to large metal fabricating shops. When plastic components just won't do, fabricate the metal equivalent using quality metal lathes that will always get the job done. Power & Hand Tools, Threaded Taper Milling Holder Mill Arbor Taper Tool Holder for Milling Cutter, End Mill Holders (MT4-FMB22 M16): Amazon.com: Industrial & Scientific . Can be used for sheet metal cutting, non-hardened blades for .Discover more about the small businesses partnering with Amazon and Amazon’s commitment to empowering them. Learn more. More results. . Jewelry Rolling Mill Machine Gear Ratio 1:2.5 Wire Roller Mill 0.1-4.5mm Press Thickness Manual Combination Rolling Mill for Metal Jewelry Sheet Square Semicircle Pattern. 0.00 $ 850. 00.Custom Titanium Iron Stainless Steel Carbon Steel Cnc Turning Parts Small Metal Cnc Milling Service For Machining Prototype. Lots of ways to do it. 1) If there is holes, drill them first and use them to hold it down 2) Vacuum (doesn't work for small parts) 3) Double sided tape 4) Hot glue. glue it and melt the glue later to get it off, and soak the part in acetone to get the glue off 5) Low-melt point metal. MSC and other places sell this stuff. It melts at a low temp, you embed your part in it, machine ..15-.59. Min. Order: 2 pieces. . ZFYL SMF-02 Custom sheet metal parts laser cutting welding sheet metal fabrication bending sheet metal stamping small part. .00-.00. Min. Order: 10 pieces.

pole mounted electrical box

Face End Mill, Mt3-Fmb22 Holder Extension 400R50-22 Face End Mill Cutter 10Pcs Apmt1604 CNC Carbide Inserts for Plate Cutting Heavy CNC Milling Cutting: Amazon.com: Industrial & Scientific . MACHINING RANGE: This MT3-FMB22 holder has better cleanliness and more stable precision, can be used for sheet metal cutting, hardened inserts for steel . Tool Clamping Form of the Tool Holder Spring cartridge tool holder. It is mainly used for straight tool holders such as drills, milling cutters and taps, or tool clamping. The elastic deformation of the circlip is 1mm, and the clamping range is 0.5~32mm in diameter.

Find your sheet metal cnc milling machine easily amongst the 19 products from the leading brands (MECANUMERIC, Joint, Gooda, .) on DirectIndustry, the industry specialist for your professional purchases. . industry for graphite machining for furniture for aeronautics for the wood industry for panels for medical applications for small parts .

Online Manufacturing for Metal parts and Plastic Parts, XTJ Precision Mfg Ltd. Mobile: +86 17704021786. Email:[email protected] . Sheet Metal Fabrication; Vacuum Casting; Plastic Injection Molding; Surface Finishing; RIM; . They are specially designed for milling small workpieces and can be used on a wide variety of materials.

Seven Successful Workholding Methods

polytec junction box

poole sheet metal

Security Boxes to fit various trail cameras.

sheet metal holder for milling small parts|Fixtures for thin sheet milling?