autocad cnc part On this episode of Make It Kustom, I walk you through drawing a part in AutoCAD to CNC plasma cutting the part. This is meant to be a introduction to the pro.

If you have a transformer box on your property, there are certain safety concerns to be aware of since one box can contain 7,200 volts of electricity. Though they look innocent, these boxes carry a deadly amount of voltage so it is vital to protect people and pets from it.

0 · free cad software for cnc

1 · free cad cam cnc

2 · cnc AutoCAD free download

3 · cad drawing for cnc machine

4 · auto cad cnc drawing

5 · AutoCAD to cnc machine

6 · AutoCAD cnc software

7 · AutoCAD cnc programming

Shelf Brackets 8 Inch Heavy Duty Metal Shelf Holders, Triangle Type with Hook Brackets for Wall Mounted Shelves Black, (2 Pack), Can bear 250 pounds, exquisite spray paint, rust and durable.

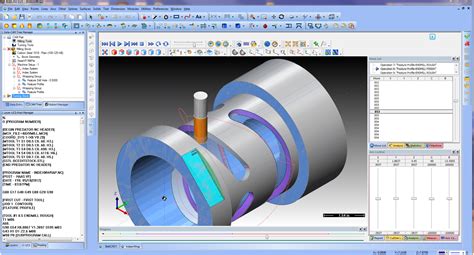

In this article, we’ll focus on getting your CAD file ready for CNC machining. In CNC machining, numerical control technology manages the machine’s work, whereby a software program is pre-made to control an object. On this episode of Make It Kustom, I walk you through drawing a part in AutoCAD to CNC plasma cutting the part. This is meant to be a introduction to the pro.

This article presents the basics on producing G-code using nothing but AutoCAD and one of its built-in programming languages. The programming language used is AutoLISP, but the article assumes the reader knows nothing about . Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code . In this article, we’ll focus on getting your CAD file ready for CNC machining. In CNC machining, numerical control technology manages the machine’s work, whereby a software program is pre-made to control an object.On this episode of Make It Kustom, I walk you through drawing a part in AutoCAD to CNC plasma cutting the part. This is meant to be a introduction to the pro.

free cad software for cnc

This article presents the basics on producing G-code using nothing but AutoCAD and one of its built-in programming languages. The programming language used is AutoLISP, but the article assumes the reader knows nothing about AutoLISP (this could also be done with VBA or VSTA).

break used in metal fabrication

This article will help you learn how to prepare CAD files for CNC machining. It discusses CAD design considerations for CNC machining and industry best practices. Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.

CNC software like Autodesk Fusion translates its CAD 3D models into G-code and toolpaths that instruct CNC machines how to create the part physically. Find out more about the types and benefits of CNC programming.Learn about CNC Programming including CNC machining, g-code and CAM/CAD. Check out Autodesk's free resources and trial for CNC Programming software. We have a solution to analyze the solids - recognizing all the holes, part sizes, applying the tool pathing, creating the CNC machine code through our post processors, etc. We connect to (create the g-code) virtually any 3-axis CNC for flat panel processing and optimization.

Using a CNC machine to produce your AutoCAD designs provides incredible time savings and precision. But this developer has created some apps for the Autodesk App Store that will give you even more tricks up your sleeve when working with files for CNC.Essentially, AutoCAD is used to create the blueprint or model for the part or component that will be produced by the CNC machine. This model is then converted into a set of instructions that the CNC machine can read, known as G-code, which tells the machine how to move and what operations to perform. In this article, we’ll focus on getting your CAD file ready for CNC machining. In CNC machining, numerical control technology manages the machine’s work, whereby a software program is pre-made to control an object.On this episode of Make It Kustom, I walk you through drawing a part in AutoCAD to CNC plasma cutting the part. This is meant to be a introduction to the pro.

This article presents the basics on producing G-code using nothing but AutoCAD and one of its built-in programming languages. The programming language used is AutoLISP, but the article assumes the reader knows nothing about AutoLISP (this could also be done with VBA or VSTA). This article will help you learn how to prepare CAD files for CNC machining. It discusses CAD design considerations for CNC machining and industry best practices. Modern CNC machining systems can interpret the part geometry directly from the 3D CAD file with the onboard computer or receive the G-code output of the CAM software.

CNC software like Autodesk Fusion translates its CAD 3D models into G-code and toolpaths that instruct CNC machines how to create the part physically. Find out more about the types and benefits of CNC programming.Learn about CNC Programming including CNC machining, g-code and CAM/CAD. Check out Autodesk's free resources and trial for CNC Programming software.

We have a solution to analyze the solids - recognizing all the holes, part sizes, applying the tool pathing, creating the CNC machine code through our post processors, etc. We connect to (create the g-code) virtually any 3-axis CNC for flat panel processing and optimization. Using a CNC machine to produce your AutoCAD designs provides incredible time savings and precision. But this developer has created some apps for the Autodesk App Store that will give you even more tricks up your sleeve when working with files for CNC.

Fusion Metalworks excels in trash enclosure gates because we understand the constant barrage and abuse a trash enclosure gate receives and pay special attention to the hinges, gate clasp .

autocad cnc part|AutoCAD to cnc machine