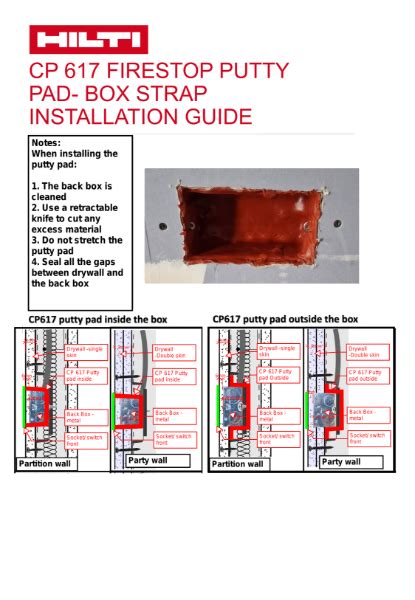

electrical back box putty pads Putty pads are designed to be applied to the external surfaces of metallic and nonmetallic switch and receptacle boxes in some rated wall conditions. We also have used putty pads in a few systems for through . When Did Metal Fencing Stop? Fences have been around for a very long time, and they have played an important role in the development of societies and economies. They have been used to protect land, and they have also been used to keep animals in or out of a property.

0 · when are putty pads required

1 · quelfire putty pads

2 · lead pads for electrical boxes

3 · intumescent putty pads electrical boxes

4 · intumescent pads for electrical sockets

5 · firestop putty for electrical boxes

6 · acoustical pads for electrical boxes

7 · acoustical outlet backer putty pad

Where Is My Breaker Box? The breaker box is going to be in a different location based on each home. There are a few restrictions on where the breaker box will be allowed and a few rules on where it must be placed. Knowing these can make it easier to find your box.

One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials. Putty pads have become a hot topic in recent months and there is often confusion over the best way to fire protect electrical back boxes in both new build and remediation .

3M™ Fire Barrier Moldable Putty Pads MPP+ are a one-part firestop material used in various fire-rated assemblies, such as electrical box protection. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent . Putty pads are designed to be applied to the external surfaces of metallic and nonmetallic switch and receptacle boxes in some rated wall conditions. We also have used putty pads in a few systems for through .Use Metacaulk Putty Pads to protect metal electrical cabinets, outlet boxes and mechanical cabinets, to maintain hourly rating of fire-rated walls with electrical outlet boxes & to reduce sound transmission, Do not expose to water.

HoldRite™ HydroFlame™ fire putty pads are a non-curing, single component, fire-rated material for membrane-penetration firestop sealants. They are ideal for protecting recessed electrical boxes – metallic and non-metallic.These putty pads for electrical boxes are sound and fire tested to maintain maximum sound and fire ratings. Each pad is a 7-1/4" square and 3/16" thick, about double the thickness of most .

One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials.

Putty pads have become a hot topic in recent months and there is often confusion over the best way to fire protect electrical back boxes in both new build and remediation situations. If you’re looking to find out more about intumescent putty .3M™ Fire Barrier Moldable Putty Pads MPP+ are a one-part firestop material used in various fire-rated assemblies, such as electrical box protection. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent material comes ready to use in convenient 1/10" (2.54 mm) thick pads that are conformable by hand with no mixing . Putty pads are designed to be applied to the external surfaces of metallic and nonmetallic switch and receptacle boxes in some rated wall conditions. We also have used putty pads in a few systems for through-penetrations.

Use Metacaulk Putty Pads to protect metal electrical cabinets, outlet boxes and mechanical cabinets, to maintain hourly rating of fire-rated walls with electrical outlet boxes & to reduce sound transmission, Do not expose to water.

HoldRite™ HydroFlame™ fire putty pads are a non-curing, single component, fire-rated material for membrane-penetration firestop sealants. They are ideal for protecting recessed electrical boxes – metallic and non-metallic.These putty pads for electrical boxes are sound and fire tested to maintain maximum sound and fire ratings. Each pad is a 7-1/4" square and 3/16" thick, about double the thickness of most putty pads. The thicker pad increases sound isolation performance as well as the fire rating. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent material comes ready to use in convenient 1/10" (2.54 mm) thick pads that are conformable by hand with no mixing or tools. Pads are firestop tested up to 2 hours.Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three sides that are away from the stud.

Firesure® putty pads for sockets and switches are an excellent solution to prevent the passage of fire through the socket and switch back boxes. These putty pads for sockets can reinstate the fire rating of a partition wall for up to two hours, making them an effective fire-stopping product.

One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials. Putty pads have become a hot topic in recent months and there is often confusion over the best way to fire protect electrical back boxes in both new build and remediation situations. If you’re looking to find out more about intumescent putty .3M™ Fire Barrier Moldable Putty Pads MPP+ are a one-part firestop material used in various fire-rated assemblies, such as electrical box protection. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent material comes ready to use in convenient 1/10" (2.54 mm) thick pads that are conformable by hand with no mixing .

Putty pads are designed to be applied to the external surfaces of metallic and nonmetallic switch and receptacle boxes in some rated wall conditions. We also have used putty pads in a few systems for through-penetrations.

Use Metacaulk Putty Pads to protect metal electrical cabinets, outlet boxes and mechanical cabinets, to maintain hourly rating of fire-rated walls with electrical outlet boxes & to reduce sound transmission, Do not expose to water.

HoldRite™ HydroFlame™ fire putty pads are a non-curing, single component, fire-rated material for membrane-penetration firestop sealants. They are ideal for protecting recessed electrical boxes – metallic and non-metallic.These putty pads for electrical boxes are sound and fire tested to maintain maximum sound and fire ratings. Each pad is a 7-1/4" square and 3/16" thick, about double the thickness of most putty pads. The thicker pad increases sound isolation performance as well as the fire rating. Designed to prevent the spread of fire, smoke and noxious gasses, this intumescent material comes ready to use in convenient 1/10" (2.54 mm) thick pads that are conformable by hand with no mixing or tools. Pads are firestop tested up to 2 hours.

Putty pads, as mentioned above, are designed to be applied to the external surfaces of metallic and nonmetallic boxes. They are applied to the back surface of the box, as well as the three sides that are away from the stud.

when are putty pads required

calculate smax for two particles distributed in two boxes

cal pac sheet metal inc

When was the first CNC machine patented? The first CNC machine was patented in 1958 by Richard Kegg, in collaboration with MIT. This groundbreaking invention, a numerically controlled milling machine, .

electrical back box putty pads|acoustical pads for electrical boxes