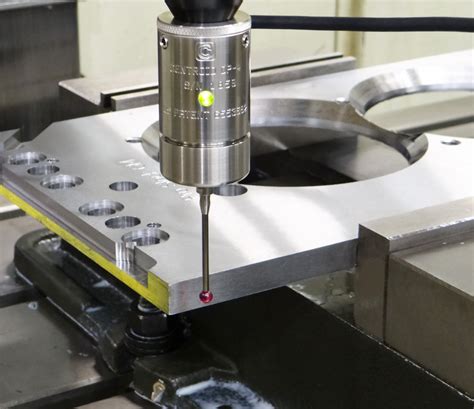

cnc machine probing milling With the probing solutions available from Haas, any machine can be set up in minutes, with just a few button pushes. Our industry-leading Wireless Intuitive Probing Systems for mills and lathes (WIPS and WIPS-L) set the standard for integrated probing systems. Get information, directions, products, services, phone numbers, and reviews on United Metal Fabricators in Johnstown, undefined Discover more Fabricated Plate Work (Boiler Shops) companies in Johnstown on Manta.com

0 · scanning probe cnc machine

1 · pros of cnc machine probing

2 · probing techniques in cnc

3 · mechanical tool probing

4 · machine tool probing systems

5 · cnc probe tool

6 · cnc machine probing problems

7 · cnc machine probing

Universal Sheet Metal Ltd. provides roofing, ventilation, and sheet metal contracting .

There are three main probing techniques in CNC machining: In contact or tactile probing, the probes touch the workpiece and maintain contact during data collection. This probing technique is favored for working with .

Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting .

scanning probe cnc machine

pros of cnc machine probing

With the probing solutions available from Haas, any machine can be set up in minutes, with just a few button pushes. Our industry-leading Wireless Intuitive Probing Systems for mills and lathes (WIPS and WIPS-L) set the standard for integrated probing systems.Set up your Haas mill up to 5 times faster using the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting . In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts. In-machine probing is a great inspection tool, but it cannot replace an .Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with .

The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished . There are three main probing techniques in CNC machining: In contact or tactile probing, the probes touch the workpiece and maintain contact during data collection. This probing technique is favored for working with larger parts, as well .Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece.With the probing solutions available from Haas, any machine can be set up in minutes, with just a few button pushes. Our industry-leading Wireless Intuitive Probing Systems for mills and lathes (WIPS and WIPS-L) set the standard for integrated probing systems.

Set up your Haas mill up to 5 times faster using the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates. In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts. In-machine probing is a great inspection tool, but it cannot replace an overall inspection strategy.Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with machine tool probing.

The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions. The probe of machine tool is the best choice of machining complex curved surface.CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes.The DATRON CNC Probe for surface mapping detects and compensates for irregular material surfaces. For milling or engraving on rounded surfaces, a probe like DATRON’s Z-Correction Probe is required and in many cases, a rotary axis is also necessary.

hyper MILL ® PROBING is the optimal CAM solution for programming measuring and probing operations directly on the machine tool. This will decrease throughput times and at the same time ensure the quality of components. A well-functioning interface between the CAM programmer and the machine operator is essential for a reliable production process. There are three main probing techniques in CNC machining: In contact or tactile probing, the probes touch the workpiece and maintain contact during data collection. This probing technique is favored for working with larger parts, as well .Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors. Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece.With the probing solutions available from Haas, any machine can be set up in minutes, with just a few button pushes. Our industry-leading Wireless Intuitive Probing Systems for mills and lathes (WIPS and WIPS-L) set the standard for integrated probing systems.

probing techniques in cnc

Set up your Haas mill up to 5 times faster using the Haas Wireless Intuitive Probing System (WIPS). WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates. In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts. In-machine probing is a great inspection tool, but it cannot replace an overall inspection strategy.Enhance the efficiency of your CNC machining centres and lathes with our innovative range of automated machine tool probes for workpiece setting and inspection. Streamline your operations and maximise your productivity with machine tool probing. The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions. The probe of machine tool is the best choice of machining complex curved surface.

CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes.The DATRON CNC Probe for surface mapping detects and compensates for irregular material surfaces. For milling or engraving on rounded surfaces, a probe like DATRON’s Z-Correction Probe is required and in many cases, a rotary axis is also necessary.

mechanical tool probing

machine tool probing systems

cnc probe tool

cnc machine probing problems

Power Exam Tables; Power Procedure Chairs; Manual Exam & Treatment Tables; Stainless Steel Storage Cabinets; Stainless Steel Foot Stools; Stainless Steel Stools; Stainless Steel – Other; Seating; Blood Draw Chairs; Pediatrics; Cabinets; Narcotic Lockers; Waste Receptacles; Design Services. Design Services; Showroom; Interior Design; Project .

cnc machine probing milling|cnc probe tool