sheet metal meaning Forming Basics. Laser Cutting. Tolerances. Features. SHEET METAL INTRODUCTION. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, .

While it's true that a metal roof will absorb heat when directly exposed to the sun, the same is true of any roof covering material. A dark colored roof in either asphalt, ceramic, slate or any other material will absorb heat at roughly the same rate.

0 · which thickness called sheet metal

1 · what is sheet metalworking

2 · what is considered sheet metal

3 · types of sheet metal material

4 · sheet metal raw material

5 · sheet metal examples

6 · different types of sheet metal

7 · characteristics of sheet metal

It may surprise some people to know that the real key to getting paint to stickâ??and stay stuckâ??to metal is all in the cleaning and surface prep. If you can be thorough with your preparation, then you can paint almost any metal .

keys for electrical enclosures

noun. : metal in the form of a sheet. Examples of sheet metal in a Sentence. Recent Examples on the . These examples are automatically compiled from online .Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than .

What is Sheet Metal? Sheet metal is metal formed by an industrial process into thin, flat pieces. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Countless . The article gives an overview of sheet metal. This includes standard measurements, materials and different forming methods. Sheet metal, to state the obvious, is metal that has been transformed into sheet form, like a sheet of plywood or a sheet of drywall. Many people equate the term “sheet metal” with the silvery or spangly-looking metal .Forming Basics. Laser Cutting. Tolerances. Features. SHEET METAL INTRODUCTION. These basic sheet metal fabrication guidelines include important design considerations to help improve part manufacturability, .

kent metal fabrications ltd brampton

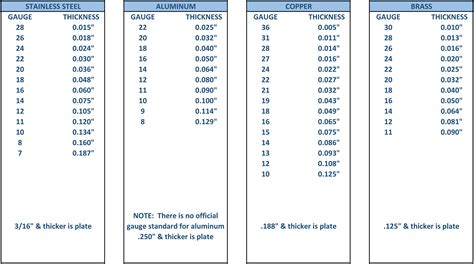

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . Sheetmetal is simply any metal alloy that stores as a sheet, or is coiled as a matter of convenience to ease handling–some coils stretch for more than a mile. Sheet metal gauge charts may seem like just numbers, but they’re vital for precision in manufacturing. Understanding these gauge numbers, which indicate material thickness in millimeters or thousandths of an inch, is crucial .Definition of Sheet Metal. In its simplest form, sheet metal is a thin, flat piece made from the more prominent metal roll. The metal sheet is uniformly thin, no more than 6mm thick. This makes it flexible and ideal for different manipulation .

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. .Definition and Concept. Sheet metal punching, or subtractive manufacturing, creates holes, slots, or shapes by applying a mechanical punch through sheet metal. The force, usually made of hardened tool steel and pierces through the metal, removes the piece, leaving a precise shape on the sheet. Shengen uses this method to meet the needs of .

Sheet metal screws can be used in a wide variety of ways. Learn more about the different types and uses of sheet metal screws. Call us today! 800.483.6354. Menu. . All Points Fasteners gives you a sheet metal screw definition, along with its different types and how to use them. We provide enough guidance to eliminate the guesswork when you .Sheet metal definition: metal in sheets or thin plates.. See examples of SHEET METAL used in a sentence.Examples of how to use “sheet metal” in a sentence from Cambridge Dictionary. A Sheet Metal Worker, or Sheet Metal Technician, works with thin sheets of metal to produce and install various types of products. On a typical Sheet Metal Work job description, their listed duties may include measuring and marking raw materials, cutting sheet metal to desired sizes using specialized equipment and fastening sheet metal into place via soldering, .

The K-Factor in sheet metal working is the ratio of the neutral axis to the material thickness. When metal is bent the top section is going to undergo compression and the bottom section will be stretched. The line where the transition from compression to stretching occurs is called the neutral axis. The location of the neutral axis varies and .The majority of bends in sheet metal are 90° bends. The K-factor must be used for all bends that are smaller or larger than 90°. SB = K(R+T) Sight line—also called the bend or brake line, it is the layout line on the metal being formed that is set even with the nose of the brake and serves as a guide in bending the work.

Hemming in sheet metal operations refers to the bending of a sheet metal edge onto itself. It is very similar to edge stitching in clothes. Similar to how an edge stitch strengthens the edge and makes it more durable, a hem imparts strength to the metal edge and improves its appearance. The edge of one part may also be folded onto another part .

Sheet Metal definition: Metal that has been rolled into a sheet having a thickness between foil and plate. Standard specification for steel sheet, metallic-coated by the hot-dip process for corrugated steel pipe. A930 – 09(2020) Standard practice for life-cycle cost analysis of corrugated metal pipe used for culverts, storm sewers, and other buried conduits. A964 / A964M – 17. Standard specification for corrugated steel box culverts Confused by sheet metal processing terminology? Our guide offers a comprehensive list of 71 key terms and definitions to help you navigate the world of sheet metal fabrication with confidence. Sheet Metal Terminology, Definitions & Phrases 2021 [Updated] Sheet metal terminology is important for beginners to understand. Below is a list of common vocabulary terms. Working with sheet metal involves many .

In this process, a flat sheet of metal, either in the form of a blank or in the form of a coil, is placed in a stamping press where a tool and die surface forms the metal into a final shape. . As its name implies, a four-slide has four slides meaning that up to four different tools, one per slide, can be used to achieve multiple bends .In sheet metal, this question always creates some confusion. What is the difference between punching blanking and piercing? Punching blanking and piercing are sheet metal shearing operations to modify existing blank. Similar . Spread. On January 1st, 2021, Twitter user BhadDhad tweeted a blank background video that only included audio of them growling, captioning it, "jackie kennedy be like," and earning roughly 8,300 views and over 230 likes in two years (shown below). The tweet was posted as a reply to a different tweet of theirs that wrote, "JACKIE WANT POPTART," and .

Definition of sheet metal While no universally accepted definition of sheet metal exists, industry consensus generally characterizes it as follows: Sheet metal refers to thin, flat metal material, typically less than 6 mm (0.25 inches) in thickness, that serves as the primary input for a comprehensive range of cold-forming manufacturing processes. Sheet metal fabrication, the practice of manipulating flat pieces of metal into new shapes, is a practical and low-cost solution for making parts like. Get Quote. . (width) and short transverse (thickness). These elongated crystals have important effects on the behavior of the metal. The mean size of each crystal, or the metal’s grain size, .

Computer skills: Modern sheet metal working is heavily reliant on computer technology, meaning that sheet metal workers need to know how to use computer software to design products and cut sheets of metal. Mathematical skills: Given the complex shapes of metal sheets created for various installations, . Sheet metal cutting, an intricate process that shapes the backbone of numerous industries, stands as a testament to human ingenuity in manufacturing. This . Metal Cutting Process: Definition, Types & Applications What is Metalworking: Definition, History, Types & Applications Water Jet Cutting Edge Quality .Sheet metal definition: metal in sheets or thin plates.. See examples of SHEET METAL used in a sentence.

Curling sheet metal is the process of adding a hollow, circular roll to the edge of the sheet. The curled edge provides strength to the edge and makes it safe for handling. . Because of this the tooling is typically unbalanced, meaning the tonnage isn’t evenly distributed front to back, so stabilizing features are sometimes incorporated . The sheet metal gauge system helps determine the thickness or diameter of different materials, such as metal and wire, based on their weight. Gauge is sometimes called “gage,” often denoted by a number followed by “ga.” The gauge chart system consists of a series of numbered gauges, with their specific thickness represented on a gauge .

which thickness called sheet metal

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, and rust or scale from ferrous metals, copper, precious metals and aluminum alloys. [1] A solution called pickle liquor, which usually contains acid, is used to remove the surface impurities.It is commonly used to descale or clean steel in various steelmaking . Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis. This versatile technique can produce a wide range of profiles, including V-shapes, U-shapes, and more complex configurations, enabling the fabrication of various components for industries such .

what is sheet metalworking

what is considered sheet metal

The reason it's a discussion is that ethernet can be susceptible to electromagnetic interference, and close proximity to power lines & sources can contribute to that. Even then, the rule is to cross the low-voltage lines perpendicular to the high-voltage lines, and avoid running them parallel to each other. Yup.

sheet metal meaning|characteristics of sheet metal