homemade cnc with 3d printed parts redesign The machine uses HTD5M belts instead of the more prevalent lead screw design. Everything slides on MGN12H slides. There are detailed photographs covering not just the tricky parts but even how to. The average hourly pay for a Fabricator is $20.50 in 2024. Visit PayScale to research fabricator hourly pay by city, experience, skill, employer and more.

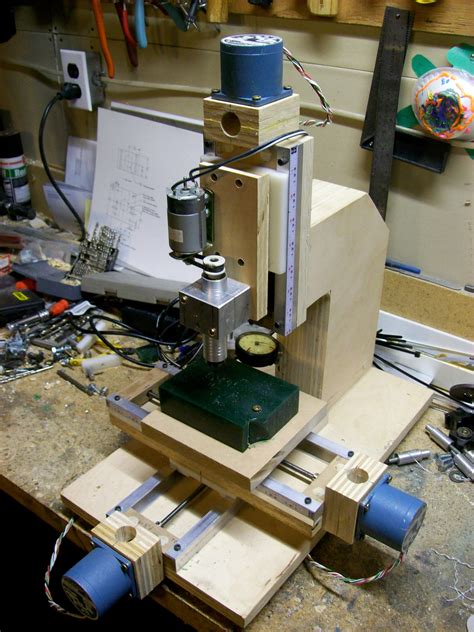

0 · diy cnc mill

1 · 3 axis cnc mill

Choosing the Right Electrical Box for Your Project. Selecting the appropriate electrical box depends on several factors, including construction, wiring method, devices, location, and safety. Type of Construction. Your .

That's why I've switched over to use 20mm x 20mm square steel tubes for both Y- and X axis. I've designed the 3D printed parts with Fusion 360 and used Inkscape for the Y axis drilling.

I’ve designed the 3D printed parts with Fusion 360 and used Inkscape for the Y axis drilling template. To control the machine I’m using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. Dive into the world of DIY as we build a one-of-a-kind, 3-axis CNC machine with a dual Y-axis, designed to precision with Marlin firmware. Witness the seamless integration of aluminum profiles,.

I've designed the 3D printed parts with Fusion 360. To control the machine I'm using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. There are plenty of tutorials to find.

The machine uses HTD5M belts instead of the more prevalent lead screw design. Everything slides on MGN12H slides. There are detailed photographs covering not just the tricky parts but even how to. One of the usual suspects, [Ivan Miranda] is at it again, this time building a knee mill from aluminum extrusions and 3D printed fittings. (Video after the break.) Most DIY CNC milling. This is a video about making my homemade DIY CNC with 3D printed parts. I’ve designed the 3D printed parts with Fusion 360. To control the machine I’m using an Arduino UNO with GRBL firmware and an Arduino CNC .DIYCNC is an online CNC 3D Printer parts store located in Ontario, Canada, which is tailored to CNC 3D printer DIY, woodworking enthusiasts, and wood project fans. 3D Printer CNC Parts Canada – Stepper Servo Motors Linear .

Hello everyone! In this video I assemble my DIY homemade CNC machine with 3d printed parts. I have been designing this machine for the last 7 months and in t.It looks like this Thing has been removed or has never existed in Thingiverse.

21 thoughts on “ DIY CNC Uses Lots Of 3D-Printed Parts ” BrightBlueJim says: November 5, 2021 at 2:02 pm NICE documentation. I also especially like that it doesn’t use expensive extrusions.

diy cnc mill

3 axis cnc mill

custom cnc turning parts factory

3D Printed 500x400mm Router CNC: First of all, I really doesn't like fuss and feathers. . it's in Portuguese). BTW, we redesign ALL the polymer parts in Autodesk Fusion 360 to make the assembly guide, so, you can ask me and I can send you the whole . (3D printed parts - green in pictures) Screws: 12x M3x20 mm ; 6x M4x25 mm ; 6x M4x35 mm .Just finished my re print of my first CNC using all leftover 3D printer parts (minus the GRBL shield) from my numerous printers over the years, and of course, 3D printed. The first one was pretty rough and printed in resin on my photon, but after realizing how terrible of an idea that was, I re designed it and beefed it up.Well, the main problem is in the lead section of the screw. When the motor takes one revolution the machine moves only 4 mm and if you are willing to make a 3 in 1 CNC in which you have to do 3D printing also so then this setup will completely fail if you increase the speed of more than 10 mm/sec because of the induced emf produced by the motors.

Update 2018/08/18: I’ve made a new version, check it out here: This is a video about making my homemade DIY CNC with 3D printed parts. I’ve designed the 3D printed parts with Fusion 360. To control the machine I’m using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. There are plenty of [.]/r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. Members Online Guy on YouTube with 4k subscribers is working on a cheap, universal, mostly 3d-printable pellet extruder, and appears to have solved most of the problems associated .The standard answer for DIY CNC at this point in time is PrintNC (r/printnc to get started, but most of the action is on their discord channel). It's a steel frame design with linear rails and ballscrews, and uses 3d printed parts to help with the construction. It may be tricky to pull in the design for your stated budget, but not impossible.

aluminum to make small combustion motors First: trying to do anything with "combustion" on a show string budget is a great way to end up in the hospital or dead. Second, there's no way you're going to achieve the tolerance you need with rotary tables built with 3D printed parts. Plastic just has too much flex and compression ability. If you added a Zero to your budget, you're starting ./r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. . Members Online • aappleking. ADMIN MOD I used 3D printing to make my own CNC machine V3! Share Add a Comment. Sort by: Best. Open comment sort options. Best. Top. New.

Update 2018/08/18: I’ve made a new version, check it out here: This is a video about making my homemade DIY CNC with 3D printed parts. I’ve designed the 3D printed parts with Fusion 360. To control the machine I’m using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. There are plenty of [.]

Building a 3D printed CNC router should only be done if you can't afford any other option. Now, that's different than having a few 3D printed parts. The PrintNC is a 95% steel router, that uses some 3D printed parts for connections. A lot of people will build the machine, and then replace them printed parts with Aluminum ones they make themselves. I had trouble with some of the 3D printed parts fitting my 2020 and 2040 extrusions. The dimensions were correct but elements were different from my extrusions. I decided to laser cut those parts which is much quicker than 3D printing when prototyping.I made a video sponsored by Banggood who have given me a 0 CNC spindle and some tooling to try and make my old Prusa i3 3D printer into a CNC. . changing the plastic parts out for something more rigid, change the belts to .

My first CNC router had Z axis 3D printed (three times, and one of them was by manufacturer), everything else made of aluminum profiles screwed together with M5 nuts and bolts (no proper nuts for . When 3D printers first made their consumer debut, they were marketed as novelty machines. This video shows numerous 3D printed parts, fixtures, organization tools, and more that are actually useful! In addition to our own examples, Jan Roetz (TIE Fighter Builder Extraordinaire) also has several awesome ideas to share. A huge thanks to him and [.]G300 - 3D Printed CNC Machine: About 6 months ago I started designing a cnc machine that allowed me to carry out some milling works; the design phase was very demanding in terms of time because it involved both the mechanical and the electronic parts. I decided to call this mac. Low Cost CNC Part V - A Redesign I've been working on a homemade CNC now for quite some time. My goal for the project was to produce something modular, where shaft-mounts, motor mounts and bearings were entirely separate parts using a standardized mounting pattern. . Like the old parts, the new parts are 3D printed, but this time on my .

/r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices. Members Online Spoiled by prusa but need my 3rd printer and need larger build volume.

This design was inspired by Nikodem Bartnik's project in order to create a machine as rigid and aesthetic as possible by using parts of 3D printers I already had. The result is much better than I expected! For more photos and videos of the machine, visit here.. Some notes: - The links in the BOM will bring you to the most appropriate items for the printed parts.The parts are printed with PLA, mostly 20% infill and 0.2 or 0.4 setting. Use higher infill for parts that must be stronger, for example the stepper motor mounts. 3D Printed components

Open source large format CNC-machine & 3d-Printer For a schoolproject we decided to build this CNC-machine. For those, wanting to view the . In the Github-Repo you can find the Documentation and CAD files for a large format CNC-machine we build with OpenBuilds parts. The total size of the machine is roughly: X: 172 cm; Y: 172 cm; Z: 128 cm .A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc . while the Shapeoko 3 was a clean-sheet redesign (only common parts were the Delrin V wheels). . /r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts .

Finishing 3D printed parts with a CNC machine makes sense when high tolerances or fine finishes are needed, as lathes and mills can take multiple passes and use multiple tools to achieve a smooth finish. It also makes sense when machining certain materials. Cutting an entire part out of a particularly hard material might cause extra wear on a .

Description from YouTube (I didn't make the video): 3D print yourself a tool to perfectly sharpen your knifes! 3 years ago my first intention with this channel was to make tech and science content but also geeky cooking videos. Well, due to time constraints I ended up only doing the first besides some sous vide cooking on live streams.

custom electrical box cover

Schlemmer Brothers Metalworks specializes in custom sheet metal fabrication. With state-of-the-art equipment, we have a wide range of capabilities including, laser cutting, machining, welding, bending, and much more.

homemade cnc with 3d printed parts redesign|diy cnc mill