05500 metal fabrications A. Metal Surfaces, General: Form metal fabrications exposed to view upon completion of the work, provide materials selected for their surface flatness, smoothness, and freedom from . Doors between garage and residence shall be 1-3/8″ minimum thick solid wood, solid or honeycomb-core steel doors not less than 1-3/8″ thick, or 20-minute fire-rated doors, equipped .

0 · STANDARD SPECIFICATIONS SECTION 05500 METAL

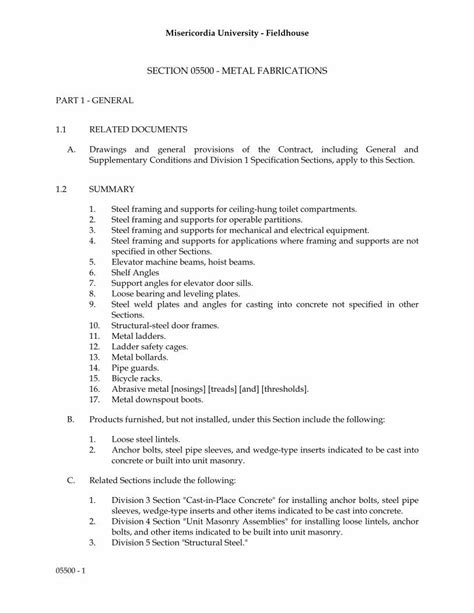

1 · SECTION 05500 METAL FABRICATIONS PART 1

2 · SECTION 05500

3 · NEW PASSENGER TERMINAL SECTION 05500

4 · Microsoft Word

5 · CONSTRUCTION STANDARD SPECIFICATION SECTION

$39.95

A. Metal Surfaces, General: Form metal fabrications exposed to view upon completion of the work, provide materials selected for their surface flatness, smoothness, and freedom from .This Section describes the requirements for furnishing and installing metal fabrications made from steel shapes, plates, bars, strips, tubes, pipes and castings not a part of structural steel or .Metal Fabrications 05500-2 of 4 Facilities Planning & Design lengths. 1.4 QUALIFICATIONS A. Prepare Shop Drawings under direct supervision of a Professional Structural Engineer .

Show sizes, finishes, locations, required hardware and accessories, and details for all fabricated metal work, threaded fasteners and welds. Indicate welds, both shop and field, by symbols . A. Fit and set metal fabrications accurately in location and securely fasten in place. B. Attached Work: Fasten metal fabrications to concrete and solid masonry with expansion .C. Shop drawings detailing fabrication and erection of each metal fabrication indicated. Include plans, elevations, sections, and details of metal fabrications and their connections.

Meet requirements specified under Structural Steel for fabricating items of structural nature or use.metal fabrications SECTION INCLUDES BASIC MATERIALS, GENERAL FABRICATION REQUIREMENTS, AND COMMONLY USED FABRICATED ITEMS. CONSULT .

changes acting on exterior metal fabrications by preventing buckling, opening of joints, overstressing of components, failure of connections, and other detrimental effects. 1.Set metal fabrications accurately in location, alignment, and elevation; with edges and surfaces level, plumb, true, and free of rack; and measured from established lines and levels.A. Metal Surfaces, General: Form metal fabrications exposed to view upon completion of the work, provide materials selected for their surface flatness, smoothness, and freedom from surface blemishes.

STANDARD SPECIFICATIONS SECTION 05500 METAL

This Section describes the requirements for furnishing and installing metal fabrications made from steel shapes, plates, bars, strips, tubes, pipes and castings not a part of structural steel or specified in other Sections, includingMetal Fabrications 05500-2 of 4 Facilities Planning & Design lengths. 1.4 QUALIFICATIONS A. Prepare Shop Drawings under direct supervision of a Professional Structural Engineer experienced in design of this work and licensed in the State of Florida.Show sizes, finishes, locations, required hardware and accessories, and details for all fabricated metal work, threaded fasteners and welds. Indicate welds, both shop and field, by symbols conforming to AWS Standards. A. Fit and set metal fabrications accurately in location and securely fasten in place. B. Attached Work: Fasten metal fabrications to concrete and solid masonry with expansion anchors and to hollow masonry with toggle bolts in cells, unless otherwise indicated.

C. Shop drawings detailing fabrication and erection of each metal fabrication indicated. Include plans, elevations, sections, and details of metal fabrications and their connections.Meet requirements specified under Structural Steel for fabricating items of structural nature or use.

metal fabrications SECTION INCLUDES BASIC MATERIALS, GENERAL FABRICATION REQUIREMENTS, AND COMMONLY USED FABRICATED ITEMS. CONSULT BROADSCOPE VERSION FOR ADDITIONAL FABRICATED ITEMS.

changes acting on exterior metal fabrications by preventing buckling, opening of joints, overstressing of components, failure of connections, and other detrimental effects. 1.Set metal fabrications accurately in location, alignment, and elevation; with edges and surfaces level, plumb, true, and free of rack; and measured from established lines and levels.A. Metal Surfaces, General: Form metal fabrications exposed to view upon completion of the work, provide materials selected for their surface flatness, smoothness, and freedom from surface blemishes.

This Section describes the requirements for furnishing and installing metal fabrications made from steel shapes, plates, bars, strips, tubes, pipes and castings not a part of structural steel or specified in other Sections, includingMetal Fabrications 05500-2 of 4 Facilities Planning & Design lengths. 1.4 QUALIFICATIONS A. Prepare Shop Drawings under direct supervision of a Professional Structural Engineer experienced in design of this work and licensed in the State of Florida.

Show sizes, finishes, locations, required hardware and accessories, and details for all fabricated metal work, threaded fasteners and welds. Indicate welds, both shop and field, by symbols conforming to AWS Standards. A. Fit and set metal fabrications accurately in location and securely fasten in place. B. Attached Work: Fasten metal fabrications to concrete and solid masonry with expansion anchors and to hollow masonry with toggle bolts in cells, unless otherwise indicated.

SECTION 05500 METAL FABRICATIONS PART 1

C. Shop drawings detailing fabrication and erection of each metal fabrication indicated. Include plans, elevations, sections, and details of metal fabrications and their connections.Meet requirements specified under Structural Steel for fabricating items of structural nature or use.metal fabrications SECTION INCLUDES BASIC MATERIALS, GENERAL FABRICATION REQUIREMENTS, AND COMMONLY USED FABRICATED ITEMS. CONSULT BROADSCOPE VERSION FOR ADDITIONAL FABRICATED ITEMS.

cnc cut off machine

cnc contour measuring machine

$9.40

05500 metal fabrications|CONSTRUCTION STANDARD SPECIFICATION SECTION