basic metal fabrication The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and . This all-steel storage cabinet features stainless steel doors with 3-point key locking system, 3 adjustable shelves, and leveling feet. Ideal for use anywhere including offices, garages, warehouses, schools, and businesses.

0 · working with sheet metal basics

1 · what is a fab shop

2 · types of sheet metal fabrication

3 · steel fabrication basics

4 · sheet metal design and fabrication

5 · materials used for fabrication

6 · how to make fabrications

7 · basics of sheet metal fabrication

500CFM 30" Wall Mount Range Hood Stainless Steel Kitchen Vent 3-Speed w/LEDs New. Ventilate Your Kitchen. Optional Carbon Filter Kit available for ductless, they can trap odors in the air and other invisible pollutants.

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, . See moreChoosing a custom metal fabrication shop or custom metal manufacturer that will best fulfill a project’s needs is an important decision that can affect the manufacturing rate, production quality, and cost-effectiveness of a given project. To help in the selection . See moreThis guide provides a basic understanding of metal fabrication, the different methods, and considerations for choosing a fabricator. For more . See more Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, .

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .

You should know a few basic things if you're new to sheet metal fabrication. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing.

In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make . Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is .

Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.Metal fabrication is a multifaceted process that combines technology, skill, and precision to transform raw materials into finished products. Each step, from design and material selection . Metal fabrication is the processing of metals to create various metal objects. The process of metal fabrication can happen in one step or can even take tens of steps, depending on what is required.

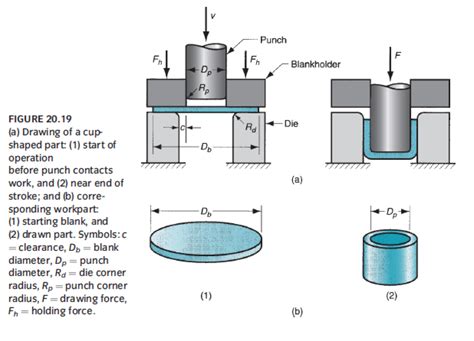

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Metal fabrication is taking a raw material, typically sheets of metal, through a series of processes to create a finished end product. Virtually every industry relies on metal fabrication to operate efficiently, create the tools they need, develop products, etc. Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, showcasing a blend of technical skills and creativity.The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies.

You should know a few basic things if you're new to sheet metal fabrication. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make informed choices for your organization.

Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is crucial for project success.

Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.

Metal fabrication is a multifaceted process that combines technology, skill, and precision to transform raw materials into finished products. Each step, from design and material selection to cutting, forming, machining, welding, and finishing, plays a crucial role in ensuring the final product meets high standards of quality and functionality. Metal fabrication is the processing of metals to create various metal objects. The process of metal fabrication can happen in one step or can even take tens of steps, depending on what is required.

junction box cover black

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Metal fabrication is taking a raw material, typically sheets of metal, through a series of processes to create a finished end product. Virtually every industry relies on metal fabrication to operate efficiently, create the tools they need, develop products, etc.

Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, showcasing a blend of technical skills and creativity.The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. You should know a few basic things if you're new to sheet metal fabrication. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make informed choices for your organization.

Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is crucial for project success. Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.Metal fabrication is a multifaceted process that combines technology, skill, and precision to transform raw materials into finished products. Each step, from design and material selection to cutting, forming, machining, welding, and finishing, plays a crucial role in ensuring the final product meets high standards of quality and functionality.

working with sheet metal basics

junction box electrical connection

junction box en español que significa

junction box drain plug

junction box explosion proof

At Toolstation, we stock a range of electrical enclosures from trusted brands like Unbranded, IMO Stag, Raytech, Axiom and Hylec. These include waterproof electrical boxes, weatherproof enclosures and junction boxes.

basic metal fabrication|what is a fab shop