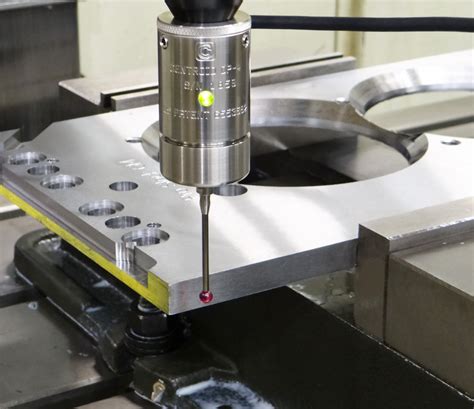

cnc probing programs to measure parts There are three main probing techniques in CNC machining: In contact or tactile probing, the probes touch the workpiece and maintain contact during data collection. This probing technique is favored for working with larger parts, as well . Look no further than Distribution Board Panels, also known as DB Panels. These essential components are the backbone of any electrical power distribution system, providing a central hub for power distribution and .

0 · tool probing and measurement

1 · probing techniques in cnc

2 · cnc tool measurement systems

3 · cnc probe tool length

4 · cnc probe tool

5 · cnc probe programming

6 · cnc machine probing system

7 · cnc machine probing software

Simply put, “metal fabrication” is defined as creating products or structures by cutting, bending, and/or assembling metal material. It’s largely considered a value-added process as it consists of putting together actual products or .

There are three main probing techniques in CNC machining: In contact or tactile probing, the probes touch the workpiece and maintain contact during data collection. This probing technique is favored for working with .Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality . There are three main probing techniques in CNC machining: In contact or tactile probing, the probes touch the workpiece and maintain contact during data collection. This probing technique is favored for working with larger parts, as well .Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality improvements.

CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes.

The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions.WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates.Make the most of your probing hardware with a choice of flexible macro and PC-based probing software for a wide range of applications and machine tool controllers. For product information, please refer to the specific product pages.

In this Tip of the Day, Mark explains how to measure parts while they are on your machine – in 5 simple steps. Probing 1-2-3-4-5! It really is as simple as learning the 5 steps Mark describes.

The XY Probing page provides several canned routines that probe sides, corners, edges, ID bores, slots, etc. All of the routines provide dimensional measurement info (CMM like usage) and the option to zero the axis to probed features (setup).Browse and download technical documentation for installation guidance and support with Renishaw machine tool probing and tool measurement systems.We can train one of your staff members to understand how to program and use it, or we can create automated custom probing programs for you. Some of the "Value Added" probing options include: Set work coordinates for part location. Automatically . There are three main probing techniques in CNC machining: In contact or tactile probing, the probes touch the workpiece and maintain contact during data collection. This probing technique is favored for working with larger parts, as well .

Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality improvements.CIMCO Probing automatically generates and inserts the machine-independant G-code directly in your NC program. Use CIMCO Probing to improve the quality of parts, increase productivity and reduce setup time and manual processes. The machine tool probing systems can be used on CNC machining centers, lathes and more equipment to identify and set up parts, monitor workpiece surface condition, measure features, and verify finished part dimensions.WIPS is a complete probing package that includes the spindle probe, tool setting probe, and optical machine interface, along with powerful software that guides the operator through the job setup process with intuitive, easy-to-use templates.

Make the most of your probing hardware with a choice of flexible macro and PC-based probing software for a wide range of applications and machine tool controllers. For product information, please refer to the specific product pages.

tool probing and measurement

probing techniques in cnc

In this Tip of the Day, Mark explains how to measure parts while they are on your machine – in 5 simple steps. Probing 1-2-3-4-5! It really is as simple as learning the 5 steps Mark describes.

The XY Probing page provides several canned routines that probe sides, corners, edges, ID bores, slots, etc. All of the routines provide dimensional measurement info (CMM like usage) and the option to zero the axis to probed features (setup).

Browse and download technical documentation for installation guidance and support with Renishaw machine tool probing and tool measurement systems.

cnc tool measurement systems

cnc probe tool length

You need an extender, something that extends out the entire box. The ones you show will work but for things like backspashes and the like this is more commonly used: http://www.aifittings.com/catalog/miscellaneous/box-extenders/BE1

cnc probing programs to measure parts|tool probing and measurement