cost of metal fabric Metal fabrics offer a wide range of characteristics to meet the aesthetic and design needs of just about any conceivable application. Choosing the right type of metal fabric is the first step and is key to providing efficient .

Premier Equipment specializes in used CNC machines with equipment such as used CNC lathes, used CNC mills and used CNC verticals. Our extensive inventory is useful to our customers who want to stay informed on brands like used Mazak, used Haas, used Doosan, used DMG Mori and used Okuma!

0 · what is metallic fabric

1 · should metallic fabric be dismantled

2 · should metallic fabric be demisted

3 · metallic fabric types

4 · metallic fabric demisted

5 · fabric construction cost per square foot

6 · can you iron metallic fabric

Browse our inventory of used CNC machines for sale and trust your next project with premier equipment’s listing and auctions. Modern used CNC lathes and turning centers provide a simulated visualization of the machine’s process and require less intimate knowledge of CNC operation than older types.

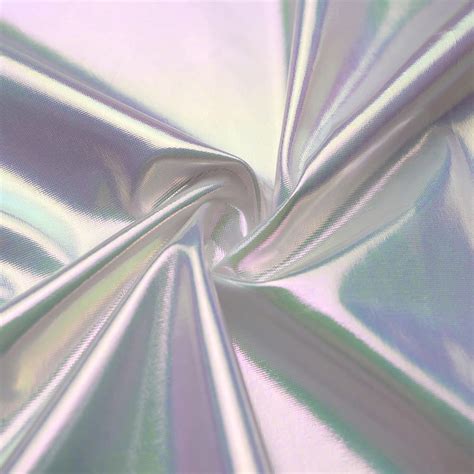

what is metallic fabric

At its minimum, a pre-engineered steel building can cost an average of per square foot and increase from there. Fabric structure costs can range between to per square foot. Construction time is a necessity in any building project.Our metal fabric designs come from the most advanced technical weaving mill in the world. See our wide range of metal mesh panels for architects and designers.

emco compact 5 cnc lathe parts

The cost of hooped barns fluctuates but depends mainly on the barn’s size and the strength of the hoops. So, expect to pay around .50/sq.ft. for a single truss kit. In comparison, a double truss costs about .80/sq.ft .These structures are designed to offer the maximum amount of usable space at the most cost-effective price, while still remaining a reliable building solution. ClearSpan’s extensive line of fabric covered buildings includes temporary .Architectural wire metal mesh material and gauge impact weight, functionality, and aesthetics – so Cascade will help you select the best material and gauge based on your architectural project requirements

Metal fabrics offer a wide range of characteristics to meet the aesthetic and design needs of just about any conceivable application. Choosing the right type of metal fabric is the first step and is key to providing efficient . "Explore the cost factors of fabric buildings in our comprehensive guide. Discover pricing insights, factors affecting costs, and tips to optimize your investment. Learn more now!"

The best way to understand the cost of a fabric structure is to request a Schedule of Value (SOV), or a breakdown of the major cost (design/engineering/project management; .Omega 1520 is a stainless steel high quality metal fabric that adds value and function to architectural applications. Omega 1520 is used for sunshade & column covers.At its minimum, a pre-engineered steel building can cost an average of per square foot and increase from there. Fabric structure costs can range between to per square foot. Construction time is a necessity in any building project.

Our metal fabric designs come from the most advanced technical weaving mill in the world. See our wide range of metal mesh panels for architects and designers. The metallic fabric’s cost depends on the product size and quality. The average cost of a metallic fabric ranges between and per yard for the different types. Metallic fabric usage and applicationsThe cost of hooped barns fluctuates but depends mainly on the barn’s size and the strength of the hoops. So, expect to pay around .50/sq.ft. for a single truss kit. In comparison, a double truss costs about .80/sq.ft .These structures are designed to offer the maximum amount of usable space at the most cost-effective price, while still remaining a reliable building solution. ClearSpan’s extensive line of fabric covered buildings includes temporary fabric buildings, portable garage and storage buildings, hoop building kits and much more.

Architectural wire metal mesh material and gauge impact weight, functionality, and aesthetics – so Cascade will help you select the best material and gauge based on your architectural project requirements Metal fabrics offer a wide range of characteristics to meet the aesthetic and design needs of just about any conceivable application. Choosing the right type of metal fabric is the first step and is key to providing efficient and cost effective solutions for your projects. "Explore the cost factors of fabric buildings in our comprehensive guide. Discover pricing insights, factors affecting costs, and tips to optimize your investment. Learn more now!" The best way to understand the cost of a fabric structure is to request a Schedule of Value (SOV), or a breakdown of the major cost (design/engineering/project management; steel, fabric and hardware fabrication; installation and equipment and shipping.)

Omega 1520 is a stainless steel high quality metal fabric that adds value and function to architectural applications. Omega 1520 is used for sunshade & column covers.At its minimum, a pre-engineered steel building can cost an average of per square foot and increase from there. Fabric structure costs can range between to per square foot. Construction time is a necessity in any building project.Our metal fabric designs come from the most advanced technical weaving mill in the world. See our wide range of metal mesh panels for architects and designers.

The metallic fabric’s cost depends on the product size and quality. The average cost of a metallic fabric ranges between and per yard for the different types. Metallic fabric usage and applicationsThe cost of hooped barns fluctuates but depends mainly on the barn’s size and the strength of the hoops. So, expect to pay around .50/sq.ft. for a single truss kit. In comparison, a double truss costs about .80/sq.ft .These structures are designed to offer the maximum amount of usable space at the most cost-effective price, while still remaining a reliable building solution. ClearSpan’s extensive line of fabric covered buildings includes temporary fabric buildings, portable garage and storage buildings, hoop building kits and much more.Architectural wire metal mesh material and gauge impact weight, functionality, and aesthetics – so Cascade will help you select the best material and gauge based on your architectural project requirements

Metal fabrics offer a wide range of characteristics to meet the aesthetic and design needs of just about any conceivable application. Choosing the right type of metal fabric is the first step and is key to providing efficient and cost effective solutions for your projects. "Explore the cost factors of fabric buildings in our comprehensive guide. Discover pricing insights, factors affecting costs, and tips to optimize your investment. Learn more now!" The best way to understand the cost of a fabric structure is to request a Schedule of Value (SOV), or a breakdown of the major cost (design/engineering/project management; steel, fabric and hardware fabrication; installation and equipment and shipping.)

should metallic fabric be dismantled

should metallic fabric be demisted

ferber sheet metal jacksonville

metallic fabric types

Tin Knocker makes 50 different new models of sheet metal working machinery, so we can provide your shop with what you need. We manufacture and sell the following machines: Bar Folders; Beaders; Benders (manual) Brakes (manual) Combination machines; Flangers and flanging attachments; Hammers; Notchers; Plasma Tables; Punches; Rolls; Roll Formers .

cost of metal fabric|fabric construction cost per square foot